SUS 2507 Stainless Steel Sheet Cold Rolled Super Duplex Plate

Product Description

Alloy 2507 (UNS S32750) is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment.

The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

The impact strength is also high. Alloy 2507 is not recommended for applications which require long exposures to temperatures above 570°F because of the risk of a reduction in toughness.

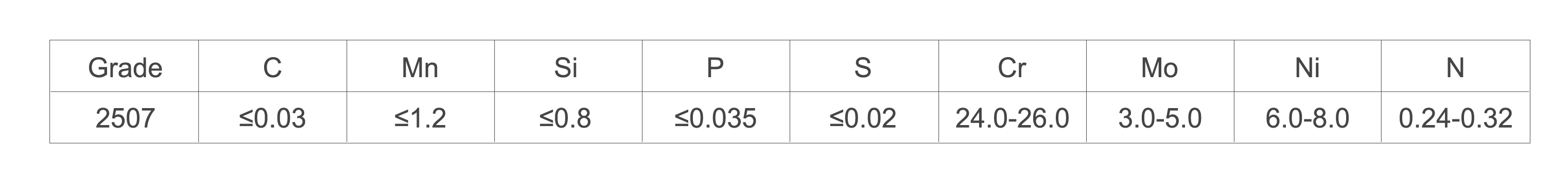

Chemical Composition (%)

Properties

2507 combines high tensile and impact strength with a low coefficient of thermal expansion and high thermal conductivity. These properties are suitable for many structural and mechanical components. The low, ambient, and elevated temperature mechanical properties of 2507 sheet and plate are shown below. All of the test data shown are for samples in the annealed and quenched condition.

2507 is not recommended for applications which require long exposures to temperatures in excess of 570°F because of the increased risk of a reduction in toughness. The data listed here are typical for wrought products and should not be regarded as a maximum or minimum value unless specifically stated.

Mechanical Properties

| 0.2% Offset Yield Strength, ksi | 80 min |

| Ultimate Tensile Strength, ksi | 116 min |

| 1% Offset Yield Strength, ksi | 91 min |

| Elongation in 2 inches, % | 15 min |

| Hardness, Rockwell C | 32 max |

| Impact Energy, ft-lbs | 74 min |

Low Temperature Impact Properties

| Temperature °F | RT | 32 | -4 | -40 |

| Ft-lbs | 162 | 162 | 155 | 140 |

| Temperature °F | -76 | -112 | -148 | -320 |

| Ft-lbs | 110 | 44 | 30 | 7 |

Elevated Temperature Tensile Properties

| Temperature °F | 68 | 212 | 302 | 392 | 482 |

| 0.2% Offset Yield Strength, ksi | 80 | 65 | 61 | 58 | 55 |

| Ultimate Tensile Strength, ksi | 116 | 101 | 98 | 95 | 94 |

Applications

systems, injection and ballast water systems

ducting, and piping

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)