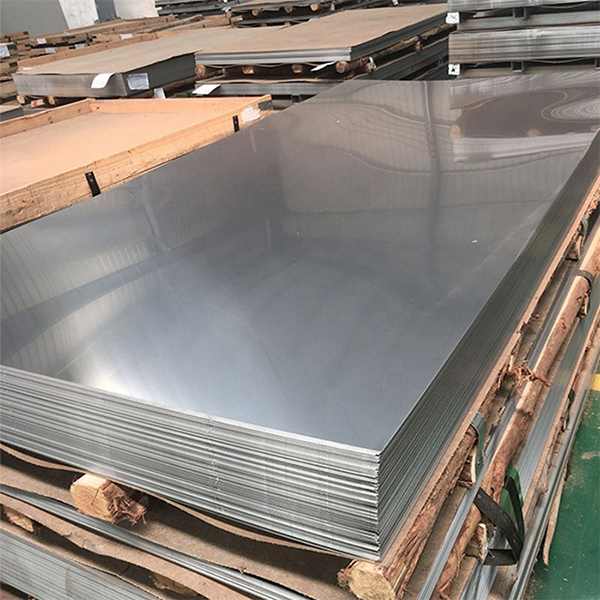

Stainless Steel Sheet 310S SS Sheet Metal 1mm 2mm 3mm 4ft X 8ft

Product Description

310S (old grade 0Cr25Ni20/ new grade 06Cr25Ni20) is an austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance, due to the higher percentage of chromium and nickel, 310S has much better creep strength, can continue to work at high temperatures, has good high temperature resistance.

Because of the high content of nickel (Ni), chromium (Cr), has good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature resistance, high temperature resistant steel pipe is dedicated to the manufacture of electric furnace tube and other occasions, austenitic stainless steel increases the content of carbon, due to its solid solution strengthening effect so that the strength is improved,

The austenitic stainless steel has high strength and creep strength at high temperature due to its face-centered cubic structure, which is based on chromium and nickel.

Chemical Composition (%)

| Grade | C | Mn | Si | P | S | Cr | Ni |

| 310S | ≤0.08 | ≤2.0 | ≤1.5 | ≤0.045 | ≤0.03 | 24.0-26.0 | 19.0-22.0 |

Corrosion Resistance

Alloy 310 is not designed for service in wet corrosive environments. The high carbon content, which is present to enhance creep properties, has a detrimental effect on aqueous corrosion resistance. The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (25%), Alloy 310 is more corrosion resistant than most heat resistant alloys.

The high chromium (25%) and silicon (0.6%) content of Alloy 310 make it more resistant to high temperature corrosion in most in-service environments. Operating temperatures are listed below.

Oxidizing conditions (max sulfur content – 2 g/m3)

1922°F (1050°C) continuous service

2012°F (1100°C) peak temperature

Oxidizing conditions (max sulfur greater than 2 g/m3)

1742°F (950°C) maximum temperature

Low oxygen atmosphere (max sulfur content – 2 g/m3)

1832°F (1000°C) maximum temperature

Nitriding or carburizing atmospheres

1562 – 1742°F (850 – 950°C) maximum

The alloy does not perform as well as Alloy 600 (UNS N06600) or Alloy 800 (UNS N08800) in reducing, nitriding or carburizing atmospheres, but it does outperform most heat resistant stainless steels in these conditions.

Creep Properties

| Temperature | Creep Strain (MPa) | Creep Rupture (MPa) | |||||

| °C | °F | 1000 H | 10000 H | 100000 H | 1000 H | 10000 H | 100000 H |

| 600 | 1112 | 120 | 100 | 40 | 200 | 140 | 80 |

| 700 | 1292 | 50 | 35 | 20 | 80 | 45 | 20 |

| 800 | 1472 | 20 | 10 | 8 | 35 | 20 | 8 |

| 900 | 1652 | 10 | 6 | 3 | 15 | 10 | 5 |

| 1000 | 1832 | 5 | 3 | 1.5 | 9 | 4 | 2 |

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)