SS Sheet Metal Inconel 625 Alloy Stainless Steel Sheet

Product Description

Alloy 625 is an austenitic nickel-chromium-molybdenum-niobium alloy possessing a rare combination of outstanding corrosion resistance coupled with high strength from cryogenic temperatures to 1800°F (982°C).

The strength of Alloy 625 is derived from the solid-solution hardening of the nickel-chromium matrix by the presence of molybdenum and niobium. Therefore, precipitation-hardening treatments are not required.

The chemical composition of Alloy 625 is also responsible for its outstanding corrosion resistance in a variety of severe operating environments along with resistance to oxidation and carburization in high temperature service. The alloy is resistant to pitting, crevice corrosion, impingement corrosion, intergranular attack and is almost immune to chloride stress corrosion cracking.

Alloy 625 can be easily welded and processed by standard shop fabrication practices.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | 58.0 min. | Silicon | 0.50 |

| Chromium | 20.0 min.-23.0 max. | Phosphorus | 0.015 |

| Molybdenum | 8.0 min.-10.0 max. | Sulfur | 0.015 |

| Iron | 5.0 | Aluminum | 0.40 |

| Niobium (plus Tantalum) | 3.15 min.-4.15 max. | Titanium | 0.40 |

| Carbon | 0.10 | Cobalt (if determined) | 1.0 |

| Manganese | 0.50 |

Mechanical Properties Typicals Values at 68°F (20°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength | Elongation in 2 in. |

Hardness |

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 65,000 | 448 | 125,000 | 862 | 50 | 200 Brinell |

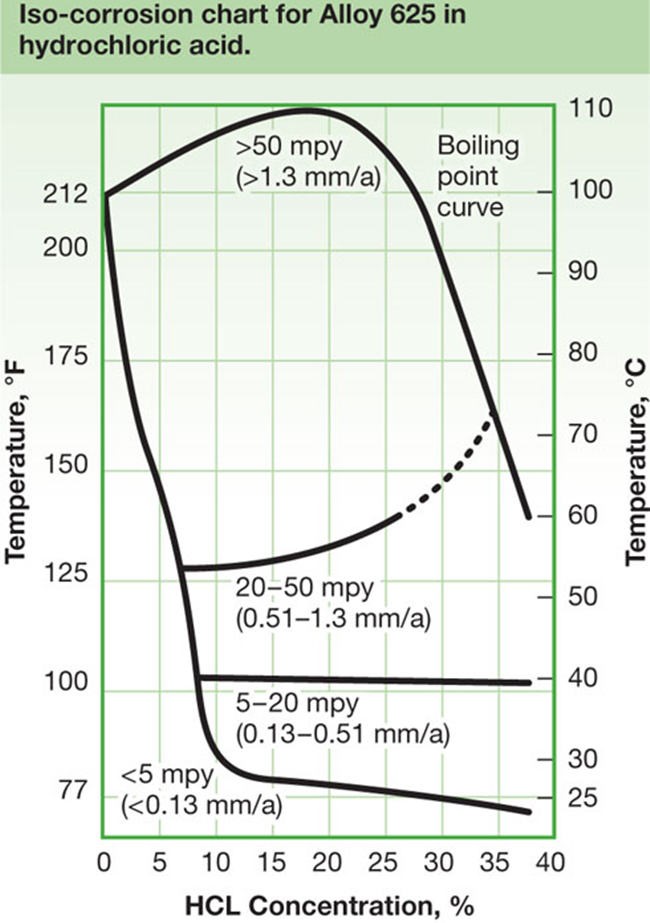

Corrosion Resistance

The highly alloyed chemical composition of Alloy 625 imparts outstanding corrosion resistance in a variety of severely corrosive environments. The alloy is virtually immune to attack in mild conditions such as the atmosphere, fresh and sea water, neutral salts and alkaline solutions. Nickel and chromium provide resistance to oxidizing solutions and the combination of nickel and molybdenum supply resistance in non-oxidizing environments. Molybdenum also makes Alloy 625 resistant to pitting and crevice corrosion, while niobium acts as a stabilizer during welding to prevent intergranular cracking. The high nickel content of Alloy 625 makes it virtually immune to chloride stress corrosion cracking.

The alloy resists attack by mineral acids such as hydrochloric, nitric, phosphoric and sulfuric, and to alkalis and organic acids in both oxidizing and reducing conditions.

Applications

systems, engine thrust-reversers, turbine shroud rings

propulsion systems

super-phosphoric acid production

.jpg)

.jpg)