NO8810 Stainless Steel Sheet Incoloy 800H SS Sheet Metal

Product Description

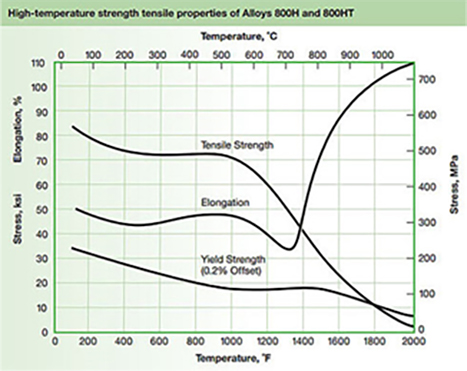

Alloy 800H has good creep-rupture properties at temperatures above 1100°F (600°C). It remains ductile during long term use at temperatures below 1290°F (700°C) due to a maximum titanium and aluminum content of 0.7%. Alloy 800 with a standard anneal is recommended for service below 1100°F (600°C). Alloy 800H resists reducing, oxidizing and nitriding atmospheres, as well as, atmospheres that alternate between reducing and oxidizing. The alloy remains stable in long term high temperature service.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Element | 800H |

| Nickel | 30.0 min.-35.0 max. |

| Chromium | 19.0 min.-23.0 max. |

| Iron |

39.5 |

| Carbon | 0.05 min.-0.10 max. |

| Manganese |

1.50 |

| Phosphorus | 0.045 |

| Sulfur | 0.015 |

| Silicon | 1.0 |

| Aluminum | 0.15 min.-0.60 max. |

| Titanium | 0.15 min.-0.60 max. |

| Aluminum & Titanium | 0.30 min.-1.20 max. |

Physical Properties

| Mean Coefficient of Thermal Expansion Temperature Range |

| °F | °C | in/in/°F | cm/cm°C |

| 200 | 93 | 7.9 x 10-6 | 14.4 x 10-6 |

| 400 | 204 | 8.8 x 10-6 | 15.9 x 10-6 |

| 600 | 316 | 9.0 x 10-6 | 16.2 x 10-6 |

| 800 | 427 | 9.2 x 10-6 | 16.5 x 10-6 |

| 1000 | 538 | 9.4 x 10-6 | 16.8 x 10-6 |

| 1200 | 649 | 9.6 x 10-6 | 17.1 x 10-6 |

| 1400 | 760 | 9.9 x 10-6 | 17.5 x 10-6 |

| 1600 | 871 | 10.2 x 10-6 | 18.0 x 10-6 |

Corrosion Resistance

The high nickel and chromium content of Alloys 800H generally means it will have very similar aqueous corrosion resistance. The alloys have corrosion resistance that is comparable to 304 when used in nitric and organic acid service. The alloys should not be used in sulfuric acid service. They are subject to chromium carbide precipitation if in service for prolonged exposure in the 1000-1400°F (538-760°C) temperature range.

Since Alloys 800H was developed primarily for hightemperature strength, corrosive environments to which these grades are exposed normally involve high temperature reactions such as oxidation and carburization.

Mechanical Properties (Typicals Values at 70°F (21°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength | Elongation in 2 in. |

Hardness |

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 29,000 | 200 | 77,000 | 531 | 52 | 126 Brinell |

Applications

ethylene dichloride, acetic anhydride, ketene, nitric acid and oxy-alcohol.

gas-cooled nuclear reactors, heat exchangers and piping systems in coal-fired power plants.

.jpg)

-150x150.jpg)

.jpg)

.jpg)