What is the ASTM A269 specification?

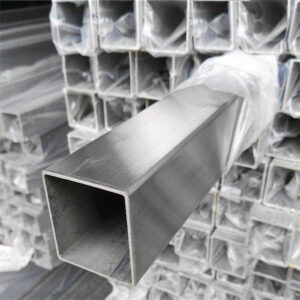

ASTM A269 is a widely recognized specification standard that provides detailed material, chemical composition, mechanical properties, physical properties, and manufacturing, testing, and labeling requirements for Austenitic stainless steel mechanical pipes used in general service. This standard plays a vital role in several industrial sectors, especially in piping systems that require high temperature and high pressure environments.

1) Applicable diameter range

The ASTM A269 specification is primarily for austenitic stainless steel seamless and welded mechanical pipes with diameters from 1/8 inch (3.2mm) to 5 inch (127mm). These pipelines are commonly used to transport gas, water, oil and other fluids, especially in high-temperature and high-pressure environments, such as chemical, oil and gas fields. By complying with ASTM A269 specifications, the quality and reliability of the pipe can be ensured to meet specific engineering requirements.

2) In terms of material and chemical composition

The ASTM A269 specification clearly defines the chemical composition range and requirements for stainless steel pipes. This provision ensures excellent corrosion resistance and mechanical properties of the pipeline. At the same time, the specification also covers a variety of stainless steel materials, including austenitic stainless steel and austenitic/ferritic stainless steel, to meet the needs of different application scenarios.

3) In terms of mechanical and physical properties

The ASTM A269 specification also has strict requirements. It specifies the mechanical properties of stainless steel pipes, such as tensile strength, yield strength and elongation. These indicators directly determine the bearing capacity and safety performance of the pipeline during use. In addition, the specification specifies physical performance requirements, such as hardness, density and coefficient of thermal expansion, to ensure that the pipe can maintain stable performance under a variety of environmental conditions.

4) In addition to material and performance requirements

The ASTM A269 specification also addresses the manufacturing process and inspection requirements of pipes. In terms of manufacturing process, the specifications specify two methods of cold drawing and cold drawing welding to ensure that the pipe has a consistent size and good mechanical properties. In terms of inspection, the specification requires physical and chemical tests to verify that the pipeline meets the specification requirements. These inspection measures ensure the quality and safety of the pipeline during production and use.

However, it is worth noting that although the ASTM A269 specification provides comprehensive guidance for the manufacture and use of stainless steel pipes, in practical applications, it is still necessary to select and adjust according to the specific working environment and engineering needs. At the same time, with the continuous progress of technology and the continuous development of the market, this specification also needs to be constantly revised and improved to adapt to new needs and challenges.

In general, ASTM A269 specification is an important reference for the manufacture and use of stainless steel pipes, which ensures the quality and performance of pipes and provides a solid guarantee for industrial development. In the future, with the continuous progress of technology and the continuous expansion of application fields, this specification will continue to play an important role in promoting the continuous development of the stainless steel pipe industry.