How to get a 2B finish on stainless steel?

Stainless steel, with its excellent corrosion resistance, beautiful appearance and strength, is widely used in construction, home decoration, medical equipment and industrial applications. In the manufacturing and processing of stainless steel, surface treatment is a crucial step, which not only determines the appearance quality of stainless steel, but also affects its corrosion resistance and service life. Among them, 2B surface treatment is a common and important surface treatment method in stainless steel processing. This article will describe in detail how to obtain the 2B surface treatment effect of stainless steel.

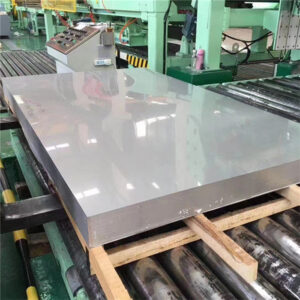

1) 2B surface treatment effect

2B surface treatment is stainless steel after cold rolling and heat treatment, and then through bright annealing and other processes to form. Its surface has a certain gloss, showing a smooth and uniform silver white, while the surface roughness is low, not easy to leave fingerprints and stains. This treatment is suitable for most indoor and outdoor environments, such as architectural decoration, home appliance housings, medical devices, etc.

2) 2B Surface treatment process

Select the right stainless steel material: First of all, to achieve the 2B effect, you must choose the stainless steel material suitable for cold rolling treatment. Different grades of stainless steel have differences in composition, organizational structure and physical properties, so when choosing, it is necessary to take into account the actual needs and use environment.

Cold rolling treatment: Cold rolling is the key step to obtain the 2B effect. The surface of stainless steel plate is deformed and shiny by continuous rolling of cold rolling machine. In the process of cold rolling, it is necessary to pay attention to the adjustment of rolling speed, rolling force and roll temperature to ensure the ideal surface effect.

Annealing treatment: The cold-rolled stainless steel plate needs to be annealed to eliminate internal stress and improve the toughness and plasticity of the material. The annealing temperature and time need to be set according to the type and thickness of the material to ensure the best annealing effect.

Surface treatment: After annealing, it is also necessary to further surface treatment of the stainless steel plate, such as pickling, passivation, etc. These treatments can remove oxides and impurities from the surface and improve the corrosion resistance of the material. At the same time, it can also be polished as needed to obtain a more uniform 2B effect.

3) Precautions

It should be noted that achieving the 2B surface treatment effect of stainless steel is not an overnight process, and it takes several attempts and adjustments to find the best process parameters. At the same time, different manufacturers and equipment may have differences in the process, so in actual operation, it is also necessary to flexibly adjust according to the specific situation.

4) Conclusion

To obtain the 2B surface treatment effect of stainless steel requires careful treatment through multiple processes. By understanding the characteristics and processes of 2B surface treatment, mastering key technologies and precautions, you can ensure that stainless steel products have excellent appearance quality and corrosion resistance. In practical applications, it is also necessary to adjust the processing process according to the specific situation to meet the needs of different customers.

Related products