Are stainless steel rods strong?

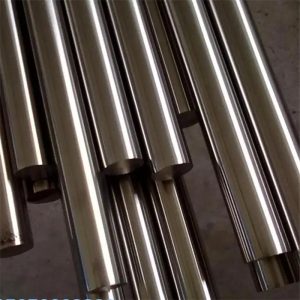

Stainless steel rod, as a common metal material, has a wide range of applications in many fields. Whether it is the construction industry, machinery manufacturing, or common furniture and decorations in daily life, stainless steel rods play an indispensable role. And its strength is the focus of many people's attention.

1) The concept of strength

In materials science, strength usually refers to the ability of a material to resist damage or deformation when subjected to external forces. For stainless steel rods, their strength is mainly affected by factors such as material composition, manufacturing process and heat treatment.

2) Chemical elements of stainless steel

Stainless steel is mainly composed of iron, chromium, nickel and other elements. Among them, the content of chromium element has a crucial impact on the corrosion resistance and strength of stainless steel. By adjusting the content and proportion of chromium, nickel and other elements in stainless steel, its strength and corrosion resistance can be optimized to meet the needs of different fields of use.

3) The manufacturing process also has an important impact on the strength of stainless steel rods.

The manufacturing process of stainless steel rod includes smelting, continuous casting, rolling and other links. In these links, strict control of process parameters to ensure the purity of the material and the uniformity of the organizational structure is essential to improve the strength of the stainless steel rod. In addition, through heat treatment such as annealing, quenching and other processes, the structure of the stainless steel rod can be adjusted to further improve its performance.

4) In practical applications

This depends on the specific use environment and requirements. In the need to withstand greater tension or pressure occasions, such as support columns in building structures, bridge rods, etc., stainless steel rods are favored for their good strength and corrosion resistance. At the same time, due to its excellent wear resistance and fatigue resistance, stainless steel rods are also widely used in the field of mechanical parts manufacturing.

5) In practical applications

This depends on the specific use environment and requirements. In the need to withstand greater tension or pressure occasions, such as support columns in building structures, bridge rods, etc., stainless steel rods are favored for their good strength and corrosion resistance. At the same time, due to its excellent wear resistance and fatigue resistance, stainless steel rods are also widely used in the field of mechanical parts manufacturing.

6) Stainless steel rods are not suitable for all occasions.

Stainless steel rods, although high strength, are not suitable for all occasions. Under certain extreme conditions, such as high temperature, high pressure or strong corrosive environments, the performance of stainless steel rods may be affected. Therefore, when choosing to use stainless steel rods, a comprehensive assessment needs to be carried out according to the specific use environment and requirements.

7) Conclusion

The stainless steel rod has shown excellent strength properties in many aspects. Through reasonable material selection and manufacturing process control, its strength and other properties can be further improved. However, when choosing to use stainless steel rods, it is still necessary to take comprehensive consideration according to the specific use environment and requirements.