Hot Rolled Stainless Steel Sheet In Coils 2205 Stainless Steel Coil

Characteristics

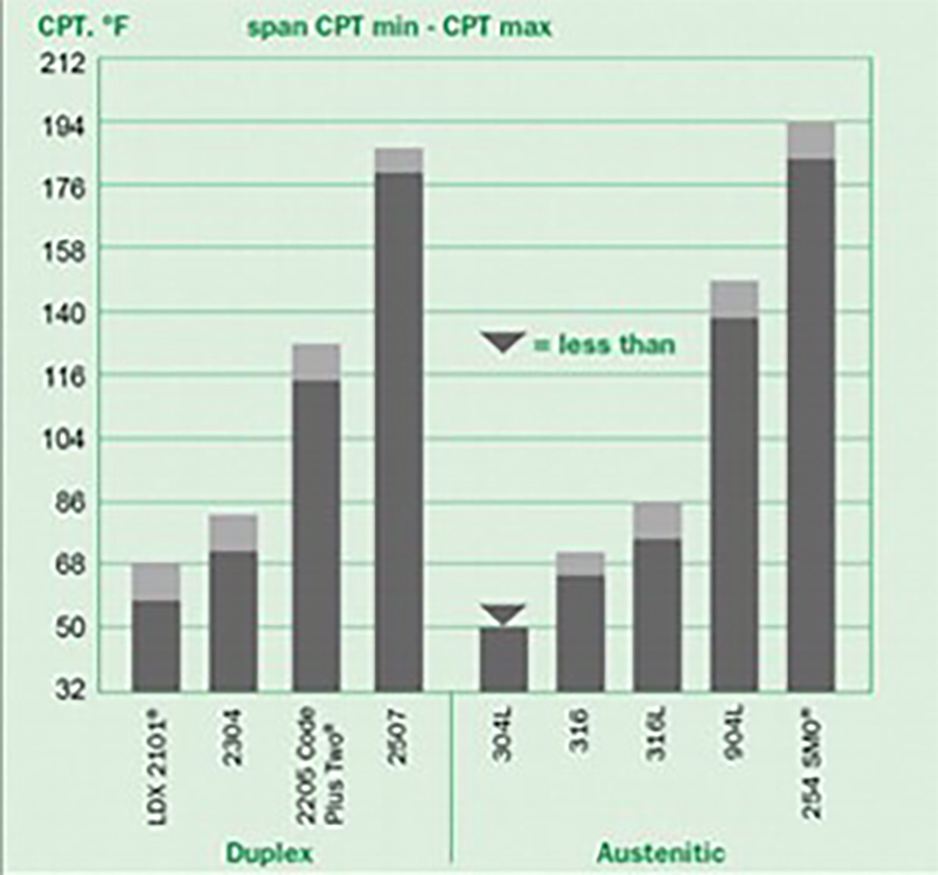

Alloy 2205 duplex stainless steel coil provides pitting and crevice corrosion resistance superior to 316L or 317L austenitic stainless coils in almost all corrosive media. It also has high corrosion and erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic.

Chemical Analysis Weight %

(all values are maximum unless a range is otherwise indicated)

| Nickel | 4.5 min.- 6.5 max. | Silicon | 1.0 |

| Chromium | 21.0 min.-24.0 max. | Phosphorus | 0.04 |

| Molybdenum | 2.5 min.- 3.5 max. | Sulfur | 0.03 |

| Nitrogen | 0.08 min - 0.2 max | Carbon | 0.03 |

| Manganese | 2.0 | Iron | Balance |

Equivalent Material

| Grade | ASTM/ASME | China GB | EURONORM | AFNOR | DIN |

| 2205 | A240 UNS S32205/S31803 | 00Cr22Ni5Mo3N | 1.4462 X2CrNiMoN 22.5.3 | Z3 CrNi 22.05 AZ | W. Nr 1.4462 |

Corrosion Resistance

Because of its high chromium (22%), molybdenum (3%), and nitrogen (0.18%) contents, the corrosion resistance properties of 2205 duplex stainless steel coils are superior to that of 316L or 317L in most environments.

The chromium, molybdenum, and nitrogen in 2205 duplex stainless steel coil also provide excellent resistance to pitting and crevice corrosion even in very oxidizing and acidic solutions.

The duplex microstructure is known to improve the stress corrosion cracking resistance of stainless steels.

Chloride stress corrosion cracking of austenitic stainless steels can occur when the necessary conditions of temperature, tensile stress, oxygen, and chlorides are present. Since these conditions are not easily controlled, stress corrosion cracking has often been a barrier to utilizing 304L, 316L, or 317L.

Alloy 2205 duplex stainless steel coil combines high strength and high corrosion resistance to produce high corrosion fatigue strength. Applications in which processing equipment is subject to both an strong corrosive environment and to cycle loading can benefit from the properties of 2205 duplex stainless steel coil.

.jpg)

.jpg)

-1.jpg)

.jpg)