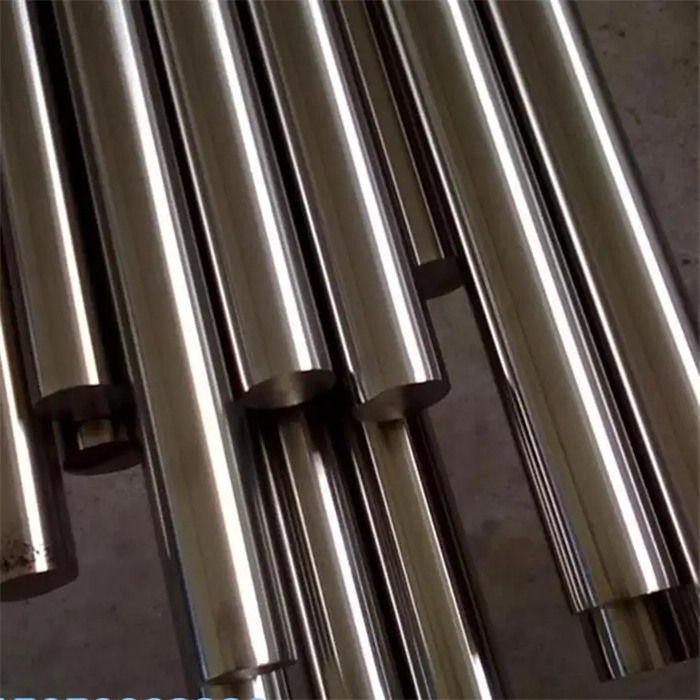

Hot Rolled 303 Stainless Steel Bars Round Hexagonal Rod Steel

Advantages

Alloy 303 (UNS S30300) is a non-magnetic, austenitic, free-machining stainless steel that is a modification of the basic 10% chromium -8% nickel stainless steel specially designed to exhibit improved machinability while maintaining good mechanical and corrosion-resistant properties. The alloy has a sulfur addition which assists in breaking up turnings while reducing drag on the cutting tool when compared to the machining characteristics of the conventional 18-8 stainless steels.

The alloy is nonmagnetic in the annealed condition , but may become slightly magnetic as a result of cold working. The addition of sulfur negatively impacts the corrosion resistance of 303 making it less resistant than 304 to mildly corrosive environments.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Chromium | 17.0 min.-19.0 max. | Sulfer | 0.15-0.35 |

| Nickel | 8.0 min.-10.0 max. | Silicon | 1.00 |

| Carbon | 0.10 | Copper | 1.00 |

| Manganese | 2.00 | Nickel | 0.110 |

| Phosphorus | 0.20 | Iron | Balance |

Mechanical Properties Typical Values at 68°F (20°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 45,000 | 310 | 85,000 | 586 | 50 | 202 (HBN) |

Fabrication Data

Annealing – Heat to a minimum temperature of 1900°F (1038°C) and water quench or rapid cool by other means.

Hardening – Alloy 303 cannot be hardened by thermal treatment, it can only be hardened by cold working.

The cold formability of Alloy 303 is adversely impacted by the high sulfur content. The alloy may be bent with a generous bend radius, however, when cold forming is required, 304 should be utilized.

The high sulfur content of Alloy 303 also has a detrimental impact on hot workability. If hot forming is required, once again, 304 should be considered as an alternate selection.

Alloy 303 was developed specifically for ease of machining. The sulfur addition assists in breaking up turnings which reduces drag on the cutting tool. It produces small brittle chips and may be machined at high speeds with deep cuts and heavy feeds.

The table below suggests speeds and feeds for various machining operations for 303.

| Machinability | High Speed Tooling | Carbide Tooling | Depth, Width or Diameter of Tool |

||

| Speed (sfm) |

Feed (in./rev.) |

Speed (sfm) |

Feed (in./rev.) |

(in.) (dia./in.) |

|

| Turning | 115 135 |

0.0150 0.0050 |

375 600 |

0.025 0.007 |

0.005-0.200 0.002-0.004 |

| Cut-off | 90 100 |

0.0015 0.0025 |

275 325 |

0.002 0.004 |

1/16 1/4 |

| Forming | 100 100 |

0.0020 0.0015 |

375 350 |

0.003 0.002 |

1 2 |

| Drilling | 70 85 100 |

0.0060 0.0100 0.0200 |

— 700 800 |

— 0.005 0.007 |

1/4 1/2 1-2 |

| Reaming | 90 90 |

0.0050 0.0150 |

— — |

— — |

1/4 1-2 |

| End Milling | 130 130 |

0.0030 0.0060 |

300 350 |

0.004 0.009 |

1/2 1-2 |

| Tapping and Threading | 10 40 |

— — |

— — |

— — |

7 threads/in. 25 theads/in. |

Alloy 303 is not recommended for applications requiring welding. If it is necessary to weld the alloy, AWS E312 filler metal may be considered.