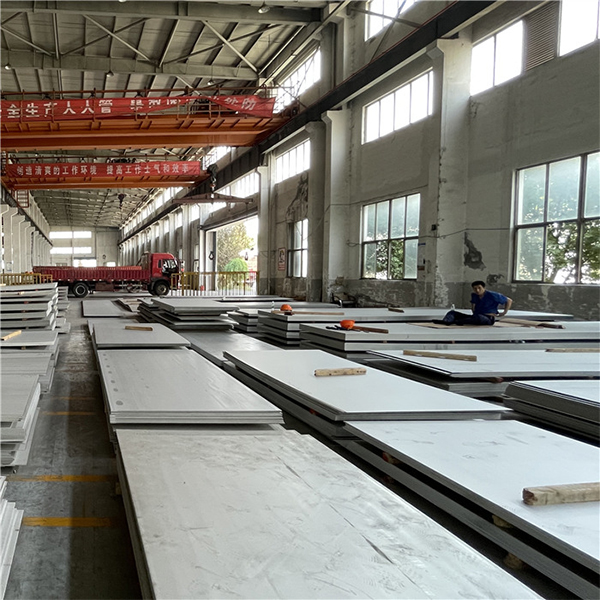

Heat Resistant SS Sheet Metal 309S Hot Rolled Stainless Steel Plate

Product Description

309S stainless steel-S30908 (American AISI, ASTM) 309S. 309S is free-cutting stainless steel containing sulfur, which is mainly used on occasions that require free cutting and high surface gloss. 0Cr23Ni13 corresponds to American standards S30908, 309S (American AISI, ASTM). 0Cr23Ni13 stainless steel has better corrosion resistance and heat resistance than 0Cr19Ni9 can withstand repeated heating below 980℃ and has higher high-temperature strength, oxidation resistance and carburization resistance.

309S (UNS S30908) is the low carbon version of the alloy. It is utilized for ease of fabrication. 309H (UNS S30909) is a high carbon modification developed for enhanced creep resistance. It most instances the grain size and carbon content of the plate can meet both the 309S and 309H requirements.

Alloy 309 can be easily welded and processed by standard shop fabrication practices.

Chemical Composition (%):

| Grade | C | Mn | Si | P | S | Cr | Ni |

| 309S | ≤0.08 | ≤2.0 | ≤1.0 | ≤0.045 | ≤0.03 | 22.0-24.0 | 12.0-15.0 |

Corrosion Resistance

Alloy 309 is not designed for service in wet corrosive environments. The high carbon content, which is present to enhance creep properties, has a detrimental effect on aqueous corrosion resistance. The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (23%), Alloy 309 is more corrosion resistant than most heat resistant alloys.

Alloy 309 resists high temperature corrosion in most in-service conditions. Operating temperatures are as follows

1922°F (1050°C) continuous service

2012°F (1100°C) peak temperature

1742°F (950°C) maximum temperature

Low oxygen atmosphere (max. sulfur content – 2 g/m3)

1832°F (1000°C) maximum temperature

1562 –1742°F (850 – 950°C) maximum

The alloy does not perform as well as Alloy 600 (UNS N06600) or Alloy 800 (UNS N08800) in reducing, nitriding or carburizing atmospheres, but it does outperform most heat resistant stainless steels in these conditions.

Applications

and retorts, recuperators, walking beams

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)

.jpg)