C-276 Stainless Steel Plate 4×8 Hastelloy Stainless Steel

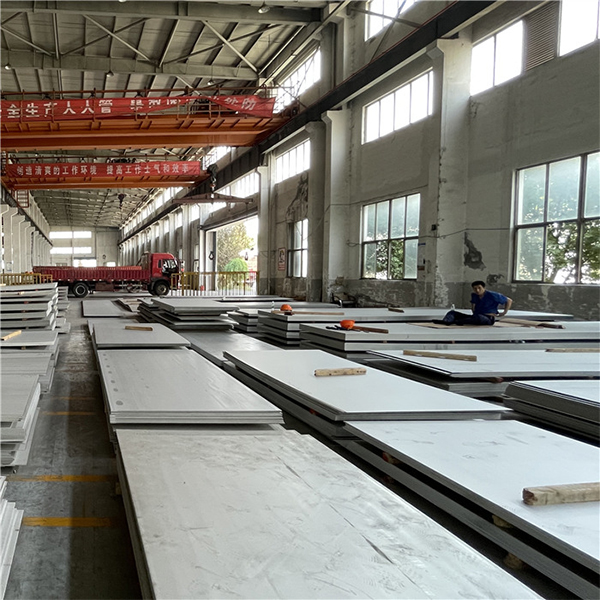

Product Description

Alloy C276 nickel alloy plate (UNS N10276) is an austenitic nickel-molybdenum-chromium alloy with a small addition of tungsten. It is one of the premier corrosion resistant materials available for process industries. Alloy C276 nickel alloy plate has excellent corrosion resistance in both oxidizing and reducing environments.The combination of the high molybdenum and chromium content, along with the addition of tungsten, make Alloy C276 nickel alloy plate highly resistant to chloride stress corrosion cracking, pitting, crevice corrosion and general corrosion.

With its highly alloyed chemistry — 25% nickel and 4.5% molybdenum, 904L provides good chloride stress corrosion cracking resistance, pitting and general corrosion resistance superior to 316L and 317L molybdenum enhanced stainless steels.

Alloy C276 nickel alloy plate can operate in oxidizing atmospheres up to 1900oF (1038oC), however, the alloy lacks sufficient chromium content to operate successfully in the most strongly oxidizing environments like hot, concentrated nitric acid.

The low carbon content of Alloy C276 nickel alloy plate enables the alloy to be utilized in the as-welded condition. It cannot be hardened by heat treatment, but can be hardened by cold working. The alloy has a higher work-hardening rate than the austenitic stainless steels which should be taken into consideration.

Alloy C276 nickel alloy plate can be easily welded and processed utilizing standard shop fabrication practices for austenitic stainless steels and nickel based alloys.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | Balance | Manganese | 1.0 |

| Molybdenum | 15.0 min.-17.0 max. | Carbon | 0.01 |

| Chromium | 14.5 min.-16.5 max. | Vanadium | 0.35 |

| Iron | 4.0 min.-7.0 max. | Phosphorous | 0.04 |

| Tungsten | 3.0 min.-4.5 max. | Sulfur | 0.03 |

| Cobalt | 2.5 | Silicon | 0.08 |

Processing Method

Alloy C276 nickel alloy plate can be easily welded and processed utilizing standard shop fabrication practices for austenitic stainless steels and nickel based alloys.

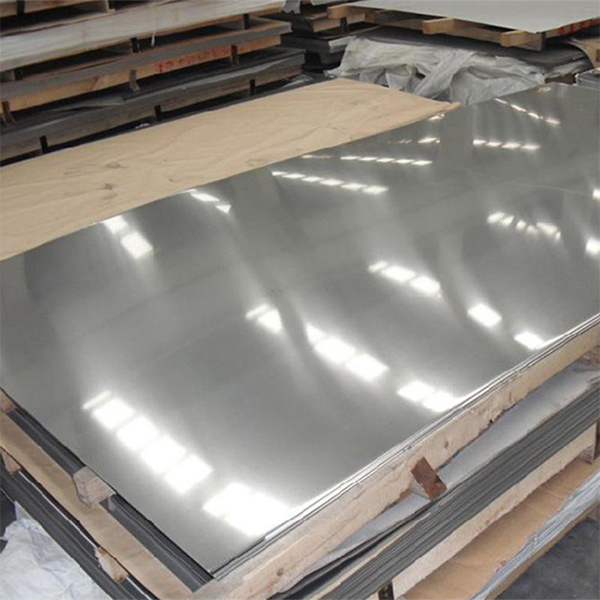

The surface has discontinuous granular shape, also known as fog surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

Cold Forming

Alloy C276 nickel alloy plate should be in the annealed condition for cold working. The alloy has a higher work-hardening rate than the austenitic stainless steels which should be taken into consideration. An in-process anneal may be necessary with a high degree of cold working. If the alloy undergoes greater than 15% deformation during cold working, a solution anneal may be necessary.

Welding

Alloy C276 nickel alloy plate can be readily welded by most standard processes including GTAW (TIG), PLASMA, GMAW (MIG/MAG) and SMAW (MMA). A post weld heat treatment is not necessary. Brushing with a stainless steel wire brush after welding will remove the heat tint and produce a surface area that does not require additional pickling.

Machining

Alloy C276 nickel alloy plate should preferably be machined in the annealed condition. Since Alloy C276 nickel alloy plate is prone to work–hardening, only low cutting speeds should be used and the cutting tool should be engaged at all times. Adequate cut depth is necessary to assure avoiding contact with the previously formed work-hardened zone.

Applications

ducts, dampers, stack gas re-heaters and fans

flanges and fittings, pumps and valves

-150x150.jpg)

.jpg)

.jpg)

.jpg)