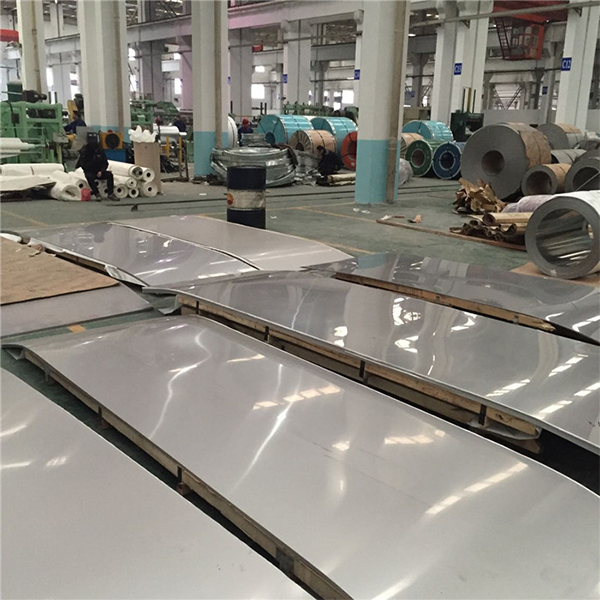

ASTM AISI SUS 409L 410 420 430 Stainless Steel Sheet Plate

Product Description

409L stainless steel sheets are highly used in many industries because of its several useful properties, it has excellent stability with good weldability, due to which it has good toughness, durability which in all results in the good life cycle of the 409L sheets. It also has a property of corrosion resistance with a high treatable method with good tensile strength and yield strength. Although the grade is anti-corrosive through which the ability of formability is excellent. Even in high temperatures the structure of the 409 sheets will function properly and can also work in high pressure too.

Chemical Composition (%)

| Grade | C | Mn | Si | P | S | Cr |

| 409L | ≤0.03 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 10.5-11.7 |

Mechanical Properties

| Gr 409L | Tensile Test | Hardness Test | Bend Test | ||||

| 0.2%Y.S. | 1%Y.S. | T.S. | EL (%) | HRBW | HV | 180° | |

| Min | 170 | — | 380 | 20 | — | — | 0.5t |

| Max | N/mm2 | — | N/mm2 | — | 88 | — | — |

Crystallization Process

Therefore, when 409L steel begins to crystallize after casting, the liquid phase has a large degree of undercooling due to direct contact with the surface of the crystallizer. At the same time, the surface of the crystallizer promotes non-spontaneous nucleation. Therefore, the nucleation rate of the liquid phase is high, forming fine equiaxed grains on the surface.

The formation rate of fine equiaxed grains on the surface is very fast, and the titanium carbide is too short to precipitate at this time. After the formation of fine equiaxed grains, columnar grains are formed in ordinary steels, but there is no columnar grains in 409L steel. The columnar grains of 409L steel are not easy to grow forward because of the narrow temperature range of liquid-solid two-phase region and the small subcooling zone during crystallization.

At the same time, after the formation of fine equiaxed crystal region, after a period of time, titanium and carbon have time to diffuse and form titanium carbide particles, promoting non-spontaneous nucleation. The above two reasons make equiaxed grains appear in this region instead of columnar grains.

There is no columnar crystal structure on the cross section, but equiaxed crystal with different sizes.

During the casting process, when the billet temperature drops to 1100℃, if the carbon content is high, part of Cr and C will form carbides, resulting in a chromium poor zone around the carbides, and a small amount of δ phase may appear.At this time, there are two phases with different properties in the steel, or the content of δ phase is between 32% and 60%, which is the plastic zone of the blank.

The carbon content of 409L steel is very low, even if δ phase is present, the amount is very small. Therefore, there is no significant impact on performance.

409L steel from high temperature to low temperature almost no α→γ phase transformation, so the grain is easy to grow up, there are thick ferrite structure, low strength, in continuous casting, after the slab is cut up, prone to bend phenomenon, affect the normal production.

The main problem during crystallization of 409L steel is the degradation of properties caused by coarse grain size≥192HB.

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

-1.jpg)

.jpg)