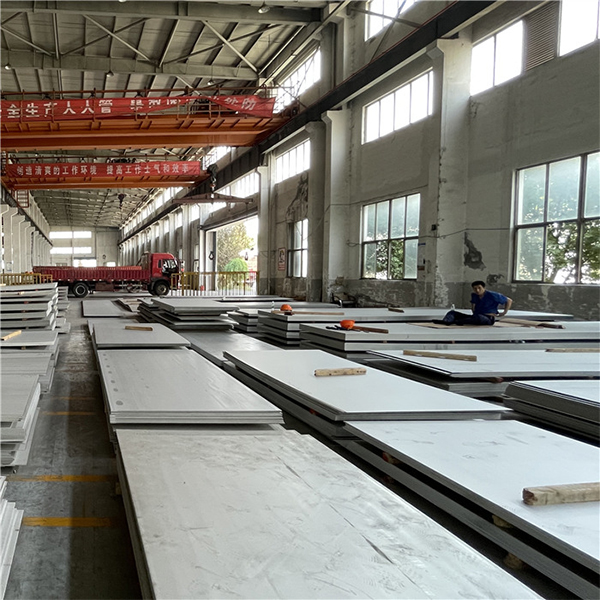

ASTM A240M Hot Rolled NO. 1 Surface 2507 Stainless Steel Sheet Coil

Characteristics

2507 is a ferritic-austenitic (duplex) stainless steel that combines the most beneficial properties of many ferritic and austenitic steels. Due to its high chromium and molybdenum content, the steel has excellent resistance to pitting, crevices and uniform corrosion.

Duplex microstructure ensures that the steel has high stress corrosion cracking resistance and high mechanical strength.

Chemical Analysis Weight %

(all values are maximum unless a range is otherwise indicated)

| Nickel | 6.0 min.- 8.0 max. | Silicon | 0.8 |

| Chromium | 24.0 min.-26.0 max. | Phosphorus | 0.035 |

| Molybdenum | 3.0 min.-5.0 max. | Sulfur | 0.02 |

| Nitrogen | 0.24 min - 0.32 max | Carbon | 0.03 |

| Manganese | 1.2 | Iron | Balance |

Physical Properties

| Interval Temper °C |

Thermal expansion ax10M-bK-1 |

°C | Resistivity

(μ_ cm) |

Thermal conductivity (W.m-1.K-1) |

Specific heat (J.kg-1.K-1) |

Young modulus E (GPa) |

Shear modulus G (GPa) |

| 20-100 | 13 | 20 | 80 | 17 | 450 | 200 | 75 |

| 20-100 | 13 | 100 | 92 | 18 | 500 | 190 | 73 |

| 20-200 | 13.5 | 200 | 100 | 19 | 530 | 180 | 70 |

| 20-300 | 14 | 300 | 105 | 20 | 560 | 170 | 67 |

Corrosion Resistance

The high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid. 2507 also provides excellent resistance to inorganic acids, especially those containing chlorides.

In dilute sulfuric acid contaminated with chloride ions, 2507 has better corrosion resistance than 904L, which is a highly alloyed austenitic steel grade specially designed to resist pure sulfuric acid.

Stainless steel of type 316L (2.5%Mo) cannot be used in hydrochloric acid due to the risk of localized and uniform corrosion. However, 2507 can be used in dilute hydrochloric acid. Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

2507's low carbon content greatly lowers the risk of carbide precipitation at the grain boundaries during heat treatment; therefore, the alloy is highly resistant to carbide-related intergranular corrosion.

The duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC). Because of its higher alloy content, 2507 is superior to 2205 in corrosion resistance and strength. 2507 is especially useful in offshore oil and gas applications and in wells with either naturally high brine levels or where brine has been injected to enhance recovery.

Different testing methods can be used to establish the pitting resistance of steels in chloride-containing solutions. The data above were measured by an electrochemical technique based on ASTM G 61. The critical pitting temperatures (CPT) of several high-performance steels in a 1M sodium chloride solution were determined. The results illustrate the excellent resistance of 2507 to pitting corrosion. The normal data spread for each grade is indicated by the dark gray portion of the bar.

The presence of crevices, almost unavoidable in practical constructions and operations, makes stainless steels more susceptable to corrosion in chloride enviroments. 2507 is highly resistant to crevice corrosion. The critical crevice corrosion temperatures of 2507 and several other high-performance stainless steels are shown above.

-1.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)