ASTM A240 Stainless Steel Plate 904L Hot Rolled Sheet

Product Description

Alloy 904L (UNS N08904) is a superaustenitic stainless steel that is designed for moderate to high corrosion resistance in a wide range of process environments. The combination of high chromium and nickel content, coupled with additions of molybdenum and copper, assure good to excellent corrosion resistance.

With its highly alloyed chemistry — 25% nickel and 4.5% molybdenum, 904L provides good chloride stress corrosion cracking resistance, pitting and general corrosion resistance superior to 316L and 317L molybdenum enhanced stainless steels.

Chemical Composition (%) & Mechanical Properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| 904L | ≤0.02 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.035 | 19.0-23.0 | 4.0-5.0 | 23.0-28.0 | 1.0-2.0 |

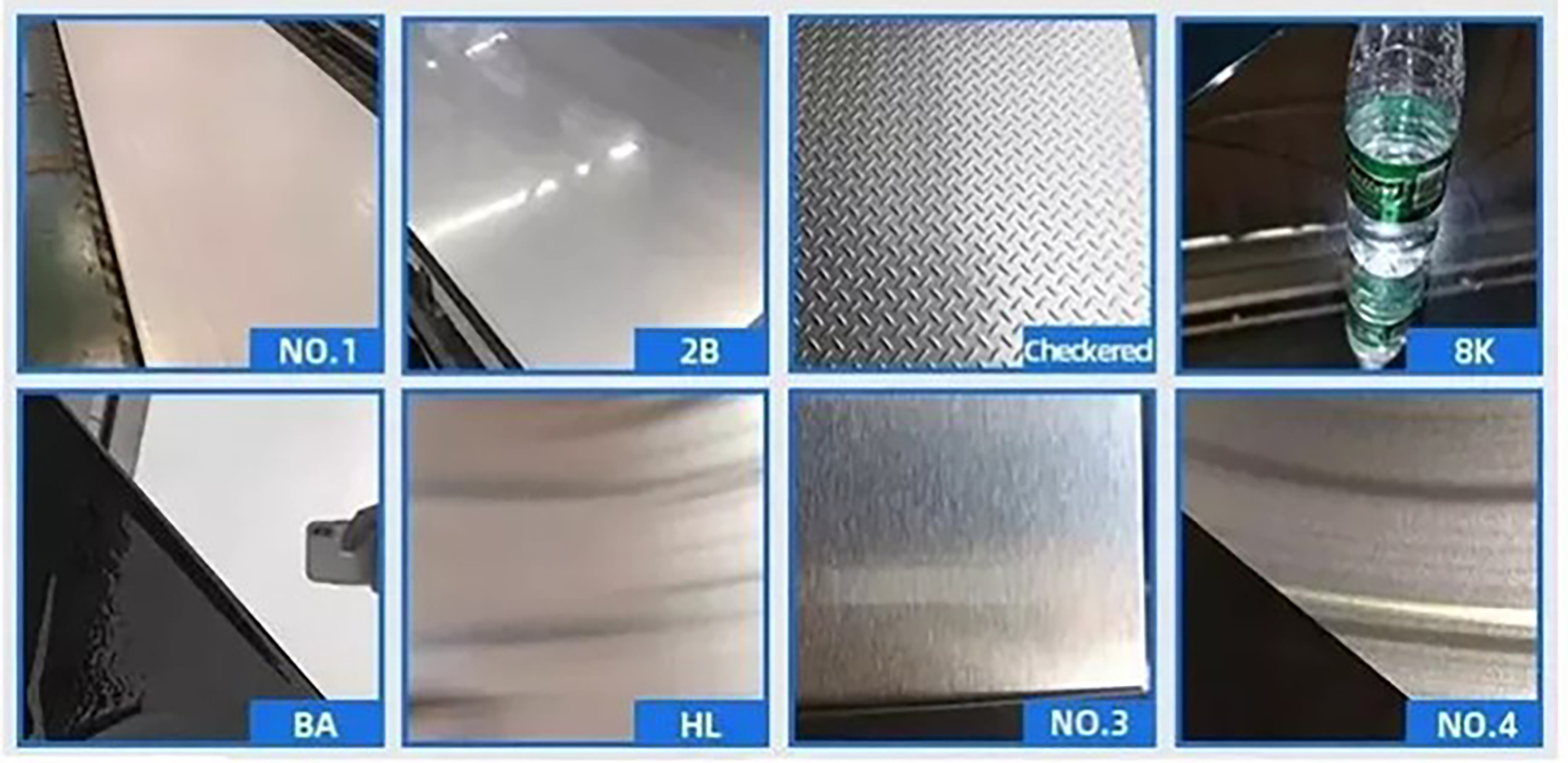

Surface Machining Technology

1D--The surface has discontinuous granular shape, also known as fog surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D--A slightly silvery white colour.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B--Silver white with better gloss and flatness than a 2D surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

Ba--Excellent surface gloss, high reflectivity, like a mirror surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenching and tempering rolling.

No.3--Good gloss, coarse grain surface.

Processing technology: polishing and tempering rolling for 2D or 2B with 100~120 abrasive materials (JIS R6002).

No.4--Good gloss, fine lines on the surface.

Processing process: polishing and tempering rolling for 2D or 2B with 150~180 abrasive materials (JIS R6002).

HL--Silver gray with hair streaks.

Processing technology: 2D products or 2B products with appropriate granularity of abrasive materials for polishing the surface is a continuous abrasive grain.

Mirror--Specular.

Processing technology: 2D products or 2B products with appropriate granularity of the grinding material grinding and polishing to the mirror effect.

Applications

flue, baffle plate, internals and spray system of the absorption tower; Scrubber and fan in organic acid treatment system.

and nitric acid equipment, acid making, pharmaceutical industry and other chemical equipment Pressure vessel, food equipment.

.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)

.jpg)