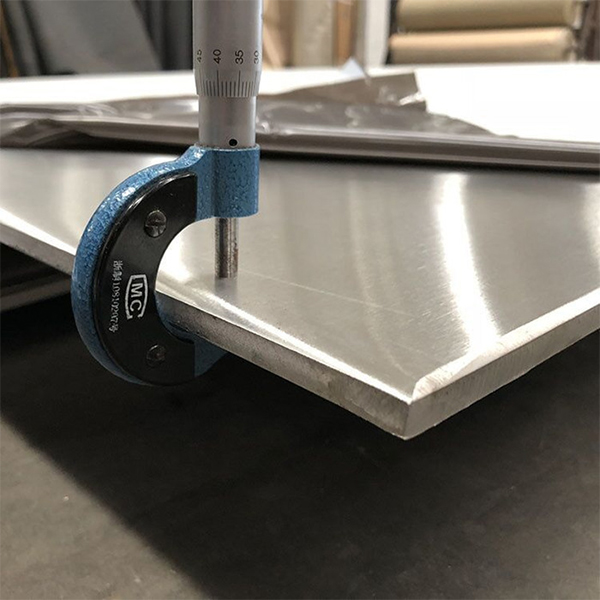

ASTM 630 Stainless Steel Plate SS Sheet Metal 3mm 4mm 5mm Thickness

Product Description

Alloy 17-4PH (UNS S17400), Type 630, is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 630 combines high strength and hardness with good corrosion resistance.

The alloy is furnished in the solution annealed condition (Condition A). It should not be used at temperatures above 572°F (300°C) or for cryogenic service. Optimal mechanical properties can be obtained by subjecting the alloy to age hardening heat treatments. Heat treatment in the 900°F (482°C) range produces the highest strength.

The corrosion resistance of Alloy 630 is comparable to 304 stainless steel in most environments, and is generally superior to the 400 series stainless steels. It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required.

Alloy 630 can be easily welded and processed by standard shop fabrication practices. It is magnetic.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Chromium | 15.0 min.-17.5 max. | Phosphorus | 0.04 |

| Nickel | 3.0 min.-5.0 max. | Sulfur | 0.03 |

| Copper | 3.0 min.-5.0 max. | Silicon | 1.0 |

| Carbon | 0.07 | Nobium plus Tantalum | 0.15 min.-0.45 max. |

| Manganese | 1.0 | Iron | Balance |

Mechanical Properties Room temperature properties (longitudinal direction)

| Heat Treatment | Yield Strength 0.2% Offset | Ultimate Tensile Strength | Elongation |

| (MPa) | ksi | (MPa) | ksi | % |

| Hardening 496 °C (925 °F) 4 h, air cooling |

Min. | 1070 | 155 | 1170 | 170 | 8 |

| Typ. | 1207 | 175 | 1310 | 190 | 14 | |

| Hardening 593 °C (1100°F) 4 h, air cooling |

Min. | 790 | 115 | 965 | 140 | 10 |

| Typ. | 931 | 135 | 1034 | 150 | 17 |

Chemical Analysis Weight %

The corrosion resistance of Alloy 630 is comparable to 304 stainless steel in most environments, and is generally superior to the 400 series stainless steels. It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required. Alloy 630 has corrosion resistance comparable to 304L in some chemical, dairy, food, paper and petroleum applications.

Alloy 630 in the solution-annealed condition (Condition A) should not generally be put in service. The alloy is subject to brittle fractures and more sensitive to chloride stress corrosion cracking than the aged material.

If risks of chloride stress corrosion cracking are present the higher aging temperatures should be selected over 1022°F (550°C), preferably 1094°F (590°C). 1022°F (550°C) is the recommended tempering temperature in chloride service. 1094°F (590°C) is preferred in H2S media.

Alloy 630 is subject to crevice corrosion and pitting attack when exposed to stagnant seawater for a duration of time.

.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)