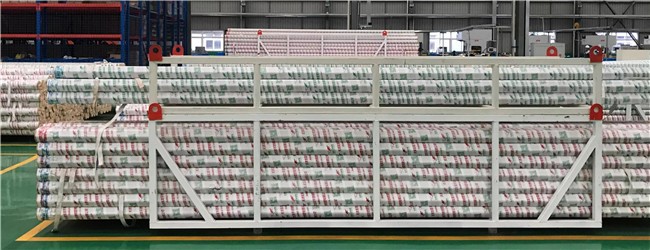

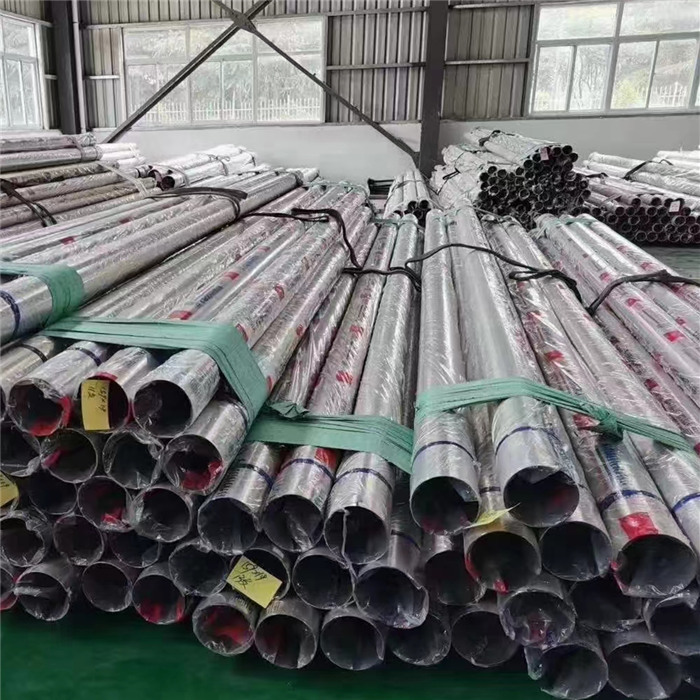

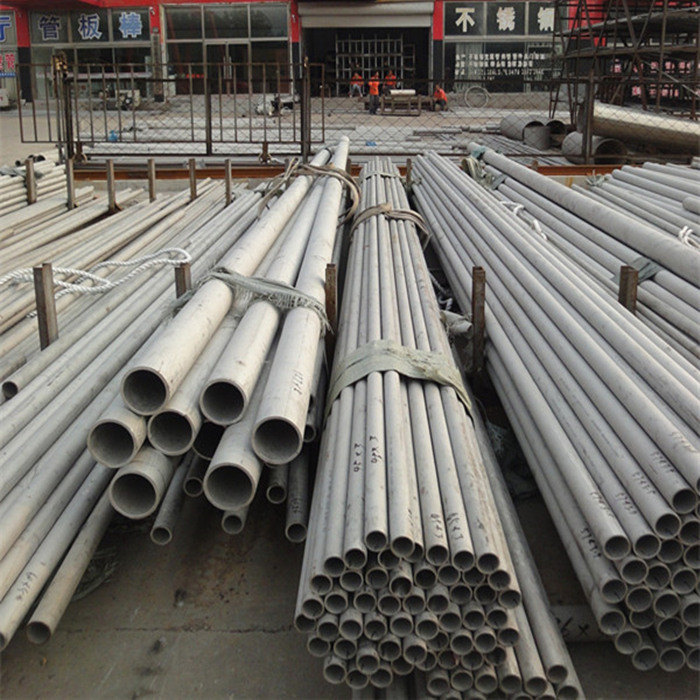

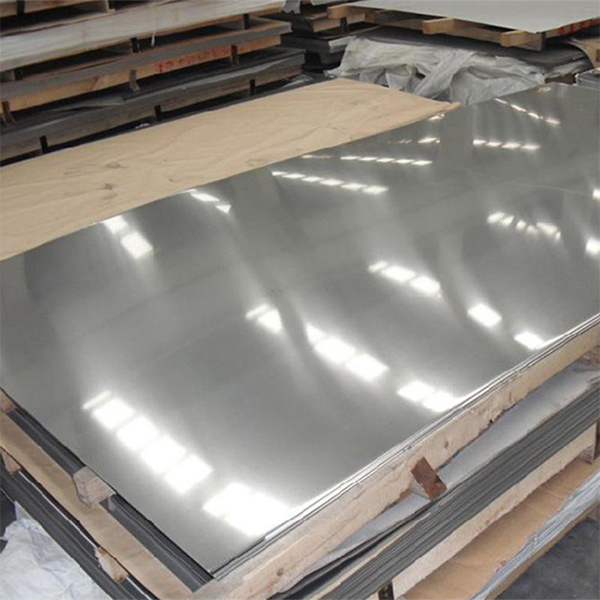

ASTM 316L Stainless Steel Pipe Welded Round Square Pipe

Overview

Alloy 316/316L (UNS S31600/S31603) is a chromium-nickelmolybdenum austenitic stainless steel developed to provide improved corrosion resistance to Alloy 304/304L in moderately corrosive environments. It is often utilized in process streams containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance. It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures.

It is common practice for 316L to be dual certified as 316 and 316L. The low carbon chemistry of 316L combined with an addition of nitrogen enables 316L to meet the mechanical properties of 316.

Alloy 316/316L resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists corrosion in polluted marine atmospheres. The alloy has excellent resistance to intergranular corrosion in the as-welded condition. Alloy 316/316L has excellent strength and toughness at cryogenic temperatures.

Mechanical Properties At Room Temperature

| ASTM | |||

| Typical | Type 316 | Type 316L | |

| 0.2% Offset Yield Strength, ksi | 44 | 30 min. | 25 min. |

| Ultimate Tensile Strength, ksi | 85 | 75 min. | 70 min. |

| Elongation in 2 inches, % | 56 | 40 min. | 40 min. |

| Reduction in Area, % | 69 | — | — |

| Hardness, Rockwell B | 81 | 95 max. | 95 max. |

Mean Coefficient of Thermal Expansion

| Temperature Range | |||

| °F | °C | in/in °F | cm/cm °C |

| 68-212 | 20-100 | 9.2 x 10-6 | 16.6 x 10-6 |

| 68-932 | 20-500 | 10.1 x 10-6 | 18.2 x 10-6 |

| 68-1832 | 20-1000 | 10.8 x 10-6 | 19.4 x 10-6 |

Applications

valves and pumps

RFQ

316L is more resistant to atmospheric corrosion than many other stainless steel grades. The combination of molybdenum and nickel make it more resistant to most environments (with the exception of nitric acid). When standing up to chloride, phosphoric, or sulfuric acid at moderate to high concentration levels, this grade shows minimal contamination, pitting, and crevice corrosion, even at sustained temperatures up to 120°F. It performs extremely well at temperatures below 100°F.

316L is the ultra low carbon variant, with just slightly less carbon at .03% vs .08%. It has a high chromium content between 18% and 20%, a nickel content between 10% and 14%, and molybdenum between 2% and 3%. The lower carbon variant performs better in corrosive environments.

The max Brinell hardness number for 316L stainless is 217.