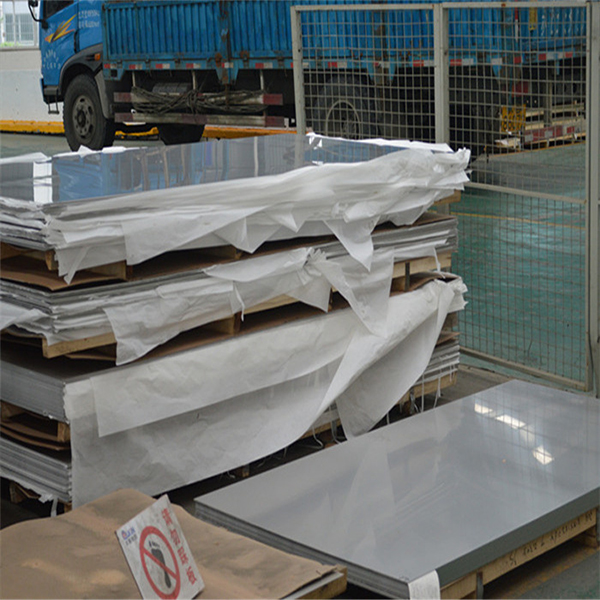

AISI 439 Stainless Steel Sheets Hot Rolled Grade Stainless Steel

Product Description

Type 439 is an 18% chromium, titanium stabilized ferritic stainless steel with corrosion resistance similar to that of 304/304L stainless steel. This grade may be used in the annealed, cold formed or as-welded condition in applications where other stainless steels such as Type 304/304L and Type 430 are used. Type 439 has good weldability due to titanium stabilization and has excellent resistance to stress corrosion cracking. Type 439 outperforms Type 409 in both oxidation and corrosion resistance and typical applications include tubular manifolds and exhaust system components.

439 grade provides excellent protection against fresh water and boiling acids at relatively high temperatures. It can resist both oxidizing environments and stress corrosion cracking. Its titanium stabilizer leads to improved welding capability and it can be work hardened to increase tensile strength. One of the disadvantages of this stainless steel grade is that it is not heat treatable.

Chemical Composition (%)

| C | Mn | P | S | Si | Cr | Ni | Ti |

| 0.03% max | 1.00% max | 0.045% | 0.045% max | 0.75% max | 17 - 19% | 0.50% | 0.50% max |

Mechanical Properties

| Metric | Imperial | |

| Tensile Strength, Ultimate | 482 MPa | 70 ksi |

| Tensile Strength, Yield | 330 MPa | 48 ksi |

| Elongation at Break (in 2") | 32% | 32% |

| Rockwell Hardness | B74 - 78 | B74 - 78 |

Applications

439 stainless steel plate is a ferritic stainless steel that is titanium stabilized. It shows excellent resistance in fresh water and boiling acids. It is a common choice for automotive exhaust systems, heat exchangers, kitchen equipment, and architectural structures.

439 stainless steel plate is seen in the automotive, architecture, food service, and appliance industries. Tubular manifolds and other automotive exhaust system components, heat exchangers, kitchen equipment and appliances are some common applications for this stainless steel grade.

FAQ

Stabilized ferritic stainless steels contain higher chromium content than martensitic steels and contain small amounts of ferrite stabilizers (i.e. titanium) which preference the ferrite phase over the austenite phase. This makes them more resistant to chloride cracking.

It melts at 2741°F (1505°C).

Deze Metal supplies 441 stainless steel in 2B and 2D, #3 and #4 polish, appliance and rolled on, and bright annealed finishes.

Our Services

test them, and give us a feedback. If you have any questions about our products, welcome to contact us, we will offer the solve way for you.

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)