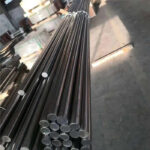

630 Stainless Steel Round Bars 17-4 Ph Grade Astm A564 Standard

Advantages

630 / 17-4PH / 1.4542 is one of the most popular and most commonly used stainless chromium-nickel alloy steels with copper additive, precipitation hardened with martensitic structure. It is characterized by high corrosion resistance while maintaining high strength properties, including hardness. Steel can operate in the temperature range from -29 ℃ to 343 ℃, while retaining relatively good parameters. In addition, the materials in this grade are characterized by relatively good ductility and their corrosion resistance is comparable to 1.4301 / X5CrNi18-10.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Chromium | 15.0 min.- 17.5 max. | Phosphorus | 0.035 |

| Nickel | 3.0 min.- 5.0 max. | Sulfur | 0.03 |

| Carbon | 0.07 | Silicon | 1.0 |

| Manganese | 1.0 | Copper | 3.0 min.- 5.0 max. |

| Niobium | 0.15 min.- 0.45 max. | Iron | Balance |

Mechanical Properties

| Condition | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation

(% in 50mm) |

Hardness | |

| Rockwell C (HR C) | Brinell (HB) | ||||

| Solution Treated | 1105 typ | 1000 typ | 15 typ | 38 max | 363 max |

| Condition 900 | 1310 min | 1170 min | 10 min | 40 min | 388 min |

| Condition 1150 | 930 min | 724 min | 16 min | 28 min | 277 min |

Fabrication Data

The corrosion resistance of Type 17-4PH / 630 is comparable to that of Type 304 Stainless Steel in most media and superior to that of the hardenable 400 series stainless steels. Refer to NACE (National Association of Corrosion Engineers) for recommendations.

Solution treatment (Condition A) — Grade 630 stainless steels are heated at 1040°C for 0.5 h, then air-cooled to 30°C. Small sections of these grades can be oil quenched.

Hardening — Grade 630 stainless steels are age-hardened at low temperatures to achieve the required mechanical properties. During the process, superficial discoloration occurs followed by shrinkage at 0.10% for condition H1150, and 0.05% for condition H900.

Grade 630 stainless steels can be welded using all conventional methods, and they do not require pre-heating. Care should be taken in designing and welding of high strength steels to prevent weldment stresses.

Grade 630 stainless steels can be machined in their solution-treated condition. They have machining rates similar to that of grade 304 steels.

Applications

630 / 17-4PH / X5CrNiCuNb16-4 / 1.4542 is provided in the form of round bars, sheets, flat bars and cold-rolled strip. The material is widely used in the aerospace, marine, paper, energy, offshore and food industries for heavy-duty machine components, bushings, turbine blades, couplings, screws, drive shafts, nuts, measuring devices.