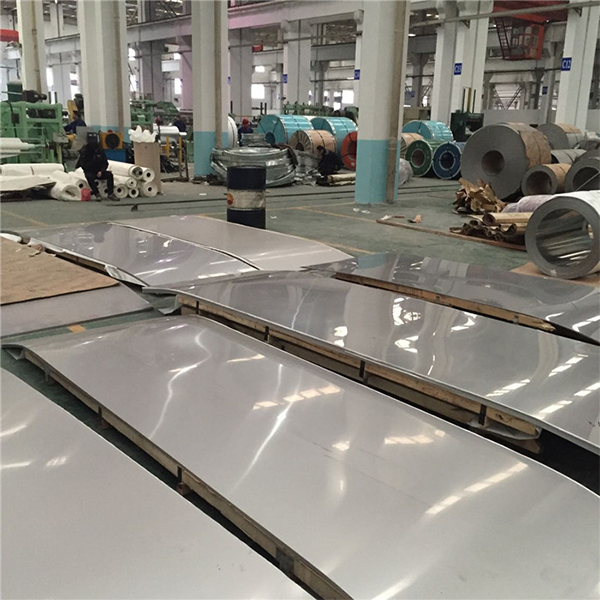

444 Stainless Steel Sheet Cold Rolled 1mm 1.5mm 2.0mm

Product Description

The yield strength of stainless steel SUS444 is 1.5 times that of carbon steel and 6 times that of FRP. It has outstanding performance for shock resistance, snow resistance, wind pressure resistance and stamping resistance.

SUS444 ferritic stainless steel has high thermal conductivity. 130%-150% of chrome-nickel austenitic stainless steel is very suitable for heat exchange applications. The coefficient of thermal expansion is small, and the squad is only 60%-70% of chrome-nickel austenitic stainless steel. It is very suitable for use under conditions of thermal expansion and contraction and thermal cycling without deformation.

The steel has good plasticity and toughness and is suitable for stretching, forming and stamping. The steel grade is the most excellent in corrosion resistance. The corrosion resistance in high chloride media is superior to that of ordinary ferritic stainless steel and austenitic stainless steel, and it does not cause stress corrosion cracking of chloride. The steel can be welded by ordinary stainless steel, especially for food processing equipment, heat exchangers, hot water tanks, water storage tanks, solar collector panels, etc.

Compared with other stainless steels, the steel is the only one that has magnetic properties. In view of this, the steel is not suitable for use in sensitive electronic equipment, electromagnetic equipment that is subject to electromagnetic waves and magnetic interference.

Chemical Analysis

SUS444 (00Cr18Mo2) is an ultra-low carbon nitrogen, 18% chromium and 2% molybdenum, high corrosion resistant ferritic stainless steel.

The steel grade is generally stabilized with tantalum or titanium to avoid intergranular corrosion after welding. This steel grade is particularly suitable for use in a variety of water treatment plants.

| C | Mn | Si | Cr | Ni |

| ≤0.025 | ≤1.00 | ≤1.00 | 17.5~19.5 | ≤1.00 |

| P | S | Mo | N | Ti+Nb |

| ≤0.04 | ≤0.03 | 1.75~2.5 | ≤0.035 | ≥0.2+4(%C+%N) |

Physical Properties

| Electrical Resistivity: microhm-in (microhm-cm) | 68 ° F (20 ° C): 22.50 (57) |

| Specific Heat: BTU/lbl° F (kJ/kg•K) | 32 - 212 ° F (0 - 100 ° C): 0.102 (0.427) |

| Thermal Conductivity: BTU/hr/ft2/ft/° F (W/m•K) |

At 212 °F (100 °C): 15.5 (26.8) |

| Mean Coefficient of Thermal Expansion: in/inl° F (µm/m•K) | 32 - 212 ° F (0 - 100 °C): 6.1 x 10-s (11.0) |

| Modulus of Elasticity: ksi (MPa) | 29 x 103 (200 x 103) in tension |

| Melting Range | 2700 - 2790 ° F (1482 - 1532 °C) |

SUS304 Stainless Steel VS SUS444 Stainless Steel

| SUS304 | 0Cr18Ni9 |

| SUS444 | 00Cr18Mo2 |

| SUS304 | Non-magnetic |

| SUS444 | Magnetic |

| SUS304 | Low carbon |

| SUS444 | Super Low Carbon |

| SUS304 | Good rust and corrosion resistance |

| SUS444 | Better rust and corrosion resistance |

| SUS304 | Brighter surface |

| SUS444 | Surface gloss |

| SUS304 | Harmless to the human body, food grade |

| SUS444 | Harmless to the human body, food grade |

-1-150x150.jpg)

.jpg)