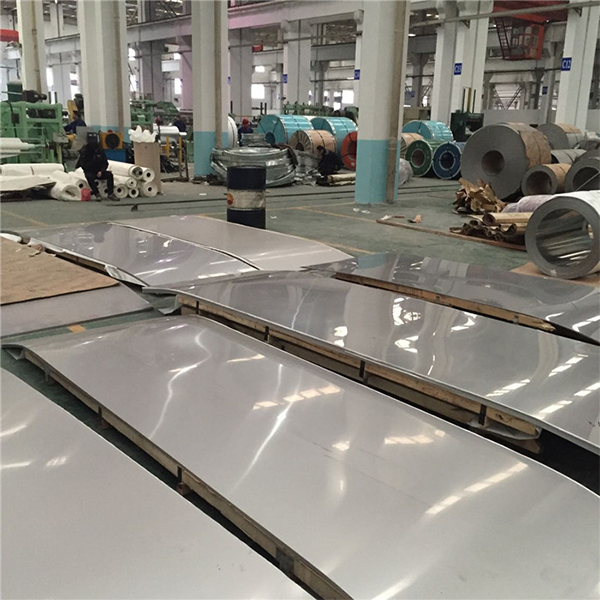

441 Stainless Steel Sheet 1.2mm 1.5mm 2.0mm Thickness

Product Description

441 stainless steel sheet is a ferritic stainless steel that is niobium stabilized. It shows good high temperature strength as well as creep, oxidation, and corrosion resistance. This stainless steel grade provides some of the best strength in high temperature and gas exhaust environments. One of the disadvantages of this stainless steel grade is that it shows diminished weld quality when compared across the 400 stainless steel category. It is not heat treatable. Type 441 Stainless Steel is a ferritic stainless steel which provides good high-temperature strength (exceeding that of Types 409 and 439 Stainless Steels) plus good corrosion resistance in many exhaust gas environments (equivalent to Type 439 and 18 Cr-Cb Stainless Steels). Ferritic steels are not inherently strong at elevated temperatures, but columbium additions coupled with appropriate solution annealing markedly improve long-time creep rupture strength. Type 441 is dual stabilized with niobium and titanium to provide good weld ductility and resistance to intergranular corrosion in the weld heat affected zone.

Chemical Composition (%)

| C | Mn | P | S | Si | Cr | Ni | Nb | N | Ti |

| 0.03 max | 1.00 max | 0.04 | 0.03 max | 1.00 max | 17.5 - 19.5 | 1.00 | 0.90 max | 0.03 max | 0.1 - 0.5 |

Mechanical Properties

| Metric | Imperial | |

| Tensile Strength, Ultimate | 490 MPa | 71 ksi |

| Tensile Strength, Yield | 324 MPa | 37 ksi |

| Elongation at Break (in 2") | 32% | 32% |

| Rockwell Hardness | B78 | B78 |

Mechanical Properties (at room temperature in annealed condition)

| Product Form | |

| Product Form | C |

| Thickness mm Max | 8 |

| Yield Strength | Rp0.2 N/mm2 | Longitudinal | 230 |

| Transverse | 250 | ||

| Tensile Strength | Rm N/mm2 | 430 - 640 | |

Applications

This grade is most suitable for drawn parts and bent tubing. Applications include

Appliances

Heat exchangers

Food and kitchen equipment

Automotive exhaust systems

FAQ

Both of these stainless steel grades have a ferritic microstructure. However, 441 has the addition of niobium as a stabilizer and a much higher chromium content. This produces a stainless steel that has more creep, corrosion, and oxidation resistance at even higher temperatures. They share many of the same applications, including automotive exhaust systems and tubular manifolds. One reason 409 might be chosen over 441 is for its improved weldability, or where end uses require significant weldments.

At 18% vs. 11%, the higher chromium content in 441 gives it the extra boost of corrosion and oxidation resistance.

Deze Metal supplies 441 stainless steel in 2B and 2D, #3 and #4 polish, appliance and rolled on, and bright annealed finishes.

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

.jpg)

.jpg)

.jpg)