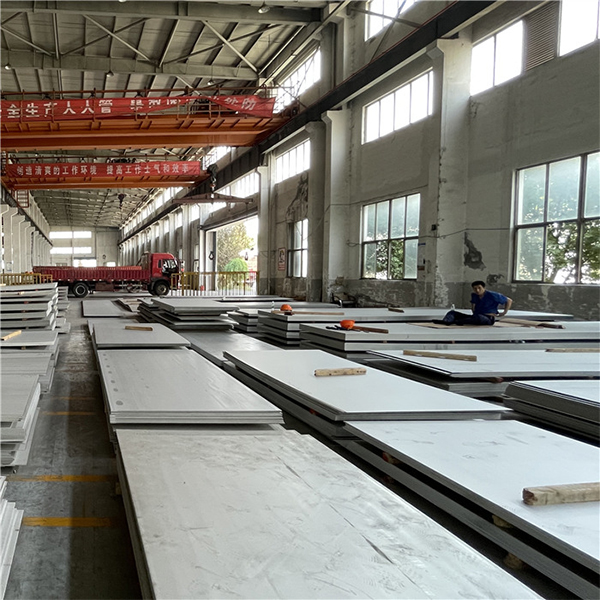

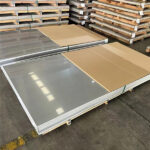

420J1 Stainless Steel Plate Hot Rolled NO.1 Surface

Product Description

420J1 stainless steel plate belongs to Cr13 type (420 series) martensitic stainless steel with high hardness and certain corrosion resistance. The products are mainly used in knives and scissors, medical equipment, food processing blades, garden tools, mechanical parts, etc.

420J1 stainless steel: high hardness after quenching, good corrosion resistance. Generally, the quenching temperature of 420J1 is 980~1050℃, the hardness of 980℃ heating oil quenching is obviously lower than 1050℃ heating oil quenching, the hardness after 980℃ oil quenching is 45-50HRC, and the hardness after 1050℃ oil quenching is 2HRC higher. However, the grains of the structure obtained after quenching at 1050°C are coarse and brittle. It is recommended to use 1000℃ heating and quenching to get better structure and hardness.

Chemical Composition (%):

| Grade | C | Mn | Si | P | S | Cr |

| 420J1 | 0.16-0.25 | ≤1.00 | ≤1.00 | ≤0.035 | ≤0.03 | 12.0-14.0 |

Processing Service

1-1: Cutting+Slitting

Flame cutting: The cost of flame cutting equipment is low and it is the only economical and effective means to cut thick metal plates, but it has its shortcomings in thin plate cutting.

Laser cutting: Laser cutting equipment can cut stainless steel plates below 30mm. Adding oxygen to the laser beam can cut 40mm thick carbon steel, but after oxygen cutting, a thin oxide film will be formed on the cutting surface.

Wire cutting: It is developed on the basis of EDM perforation and forming. It has not only developed the application of EDM but also replaced EDM perforation and forming in some aspects.

Shearing cutting: Uses a moving upper blade and a fixed lower blade and uses a reasonable blade gap to apply shearing force to metal plates of various thicknesses so that the plates can be broken and separated according to the required size. Shearing machine is a kind of forging machinery, and its main function is the metal processing industry.

Plasma cutting: It is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece and uses the momentum of the high-speed plasma to remove the molten metal to form an incision.

Slitting: Also known as slitting, refers to the process of uncoiling, slitting, leveling, and winding of stainless steel coils into coils of the required width.

1-2: Surface processing - 8K mirror, HL hairline, color coating

1-3: Bending+Welding - OEM customized products as drawing

Applications

| 420J1 Stainless Steel Plate Used in Tractor |

| 420J1 Stainless Steel Plate Used in Automotive Trim |

| 420J1 Stainless Steel Plate Used in Stamped Machined Products |

| 420J1 Stainless Steel Plate Used in Cookware |

| 420J1 Stainless Steel Plate Used in Appliances |

| 420J1 Stainless Steel Plate Used in Kitchen |

| 420J1 Stainless Steel Plate Used in Food Service Equipment |

| 420J1 Stainless Steel Plate Used in Sinks |

| 420J1 Stainless Steel Plate Used in Railway Cars |

| 420J1 Stainless Steel Plate Used in Trailers |

.jpg)

.jpg)

.jpg)

.jpg)