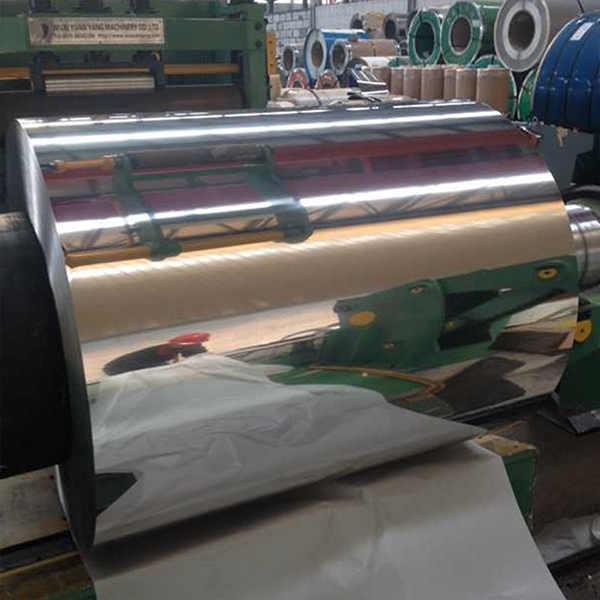

410S Stainless Steel Sheet Coil Finish Cold Rolled Slit

Characteristics

Stainless steel 410S is produced in accordance with the American ASTM standard of stainless steel, equivalent to China's 1Cr13 stainless steel, S41000 (AISI, ASTM).

0.15% carbon, 13% chromium,410S stainless steel: good corrosion resistance, machinability, general purpose blade, valve type.

Heat treatment of stainless steel: solution treatment (℃) 800-900 slow cooling or 750 fast cooling

Chemical Analysis Weight %

(all values are maximum unless a range is otherwise indicated)

| Nickel | 0.6 | Silicon | 1.0 |

| Chromium | 11.5 min.- 13.5 max. | Phosphorus | 0.04 |

| Molybdenum | - | Sulfur | 0.03 |

| Nitrogen | - | Carbon | 0.08 |

| Manganese | 1 | Iron | Balance |

Features

Corrosion Resistance

The corrosion resistance of 410S stainless steel is similar to type 410. It resists corrosion in atmospheric conditions, fresh water, mild organic and mineral acids, alkalis and some chemicals. It’s exposure to chlorides in everyday activities (e.g., food preparation, sports activities, etc.) is generally satisfactory when proper cleaning is performed after exposure to use.

| 5% Test Solution at 120°F (49°C) |

Corrosion Rate in Mils per Year and Millimeters per Year (mm/a) | |||||

| Alloy 409 | Alloy 410S | Alloy 420 | Alloy 425 Mod | Alloy 440A | Alloy 430 | |

| Acetic Acid | 0.88 (0.022) |

0.079 (0.002) |

1.11 (0.028) |

4.79 (0.122) |

2.31 (0.0586) |

0.025 (0.0006) |

| Phosphoric Acid | 0.59 (0.002) |

0.062 (0.002) |

0.068 (0.002) |

0.593 (0.015) |

0.350 (0.009) |

0.029 (0.001) |

*Hardened martensitic grades were tested after tempering at 400°F (204°C)

As shown in the above table, 410S has good corrosion resistance to low concentratiions of mild organic and mineral acids.

The oxidation resistance of 410S stainless steel is good. It can be used in continuous service up to 1300°F (705°C). Scaling becomes excessive above 1500°F (811°C) in intermittent service.

410S stainless steel can be easily formed by spinning, bending and roll forming.

Applications

.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

-1.jpg)

-2.jpg)

.jpg)