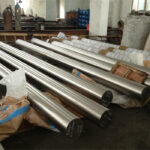

410 Stainless Steel Bars Round Square Bars ASTM AISI 3mm 4mm 5mm 6mm

Advantages

Alloy 410 (UNS S41000) is a 12% chromium martensitic stainless steel bar that can be heat treated to obtain a wide range of mechanical properties. The alloy has good corrosion resistance along with high strength and hardness. In the annealed condition, 410 stainless steel bar is ductile and may be formed. It remains magnetic in both the annealed and heat treated conditions.

Chemical Analysis Weight % (all values are maximum unless a range is otherwise indicated)

| Chromium | 11.5 min.-13.5 max. | Phosphorus | 0.04 |

| Nickel | 0.75 | Sulfur | 0.03 |

| Carbon | 0.08 min.-0.15 max. | Silicon | 1.0 |

| Manganese | 1.0 | Iron | Balance |

Corrosion Resistance

Alloy 410 stainless steel bar is resistant to atmospheric conditions, water and some chemicals. It can be used in environments containing weak or diluted acetic acid, naptha, nitric acid and sulfuric acid. The alloy is also resistant to acids contained in foods.

410 stainless steel bar can also be used in slightly chlorinated and desaereted water. It performs well in oil and gas applications where desaereted and low hydrogen sulfide exist. However, the alloy is prone to chloride attack, particularly in oxidizing conditions.

410 stainless steel bar operates well in environments requiring moderate corrosion resistance and high mechanical properties.

Oxidation Resistance

Alloy 410 stainless steel bar resists oxidation up to 1292°F (700°C) continuously, and up to 1500°F (816°C) on an intermittent basis.

Properties

| Mechanical Properties Typical Values at 68°F (20°C) | |||||

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

| psi | (MPa) | psi | (MPa) | % | (max.) |

| 42,000 | 290 | 74,000 | 510 | 34 | 96 Rb |

| Specific Heat | 0.11 BTU/lb-°F (32 – 212°F) 0.46 J/kg-°K (0 – 100°C) |

| Modulus of Elasticity | 29.0 x 106 psi 200 GPa |

| Thermal Conductivity 200°F (100°C) | 14.4 BTU/hr/ft2/ft/°F 24.9 W/m-°K |

| Melting Range | 2700 – 2790°F 1480 – 1530°C |

| Electrical Resistivity | 22.50 Microhm-cm at 68°C 57 Microhm-cm at 20°C |

Fabrication Data

Annealing – Heat slowly to 1500 – 1650°F (816 – 899°C), cool to 1100oF (593°C) in furnace, air cool

Process Annealing – Heat to 1350 – 1450°F (732 – 788°C), air cool

Hardening – Heat to 1700 – 1850°F (927 – 1010°C), air cool or oil quench. Follow by stress-relief or temper

Stress Relieving – Heat to 300 – 800°F (149 – 427°C) for 1 to 2 hours, air cool

Tempering – Heat to 1100 – 1400°F (593 – 760°C) for 1 to 4 hours, air cool

The alloy can be cold worked with moderate forming in the annealed condition.

It is typically done in the 1382 – 2102°F (750 – 1150°C) range followed by air cooling.

Alloy 410 stainless steel bar is best machined in the annealed condition at surface speeds of 60 – 80 feet (18.3 – 24.4m) per minute. Post machining decontamination and passivation are recommended.

Alloy 410 stainless steel bar is best machined in the annealed condition at surface speeds of 60 – 80 feet (18.3 – 24.4m). Due to its martensitic structure, alloy 410 stainless steel bar has limited weldability because of its hardenability.