409L Stainless Steel Strips Cold Rolled Stainless Steel Strip In Coil

Features

409L is the most widely used chromium nickel stainless steel with good corrosion resistance, heat resistance, low temperature strength and mechanical properties. It is resistant to corrosion in the atmosphere. If it is an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for food processing, storage and transportation. It has good processability and weldability. It is widely used in plate heat exchanger, corrugated pipe, household goods, building materials, chemistry, food industry, etc.

Chemical Composition (%)

| Element | Minimum percentage | Maximum percentage |

| C | – | 0.03 |

| Si | – | 1.0 |

| Mn | – | 1.0 |

| P | – | 0.04 |

| S | – | 0.03 |

| Cr | 10.5 | 11.7 |

Mechanical Properties

| Metric | Imperial | |

| Tensile Strength, Ultimate | 380 MPa | 55 ksi |

| Tensile Strength, Yield | 207 MPa | 30 ksi |

| Elongation at Break (in 2") | 20% | 20% |

| Rockwell Hardness | B95 | B95 |

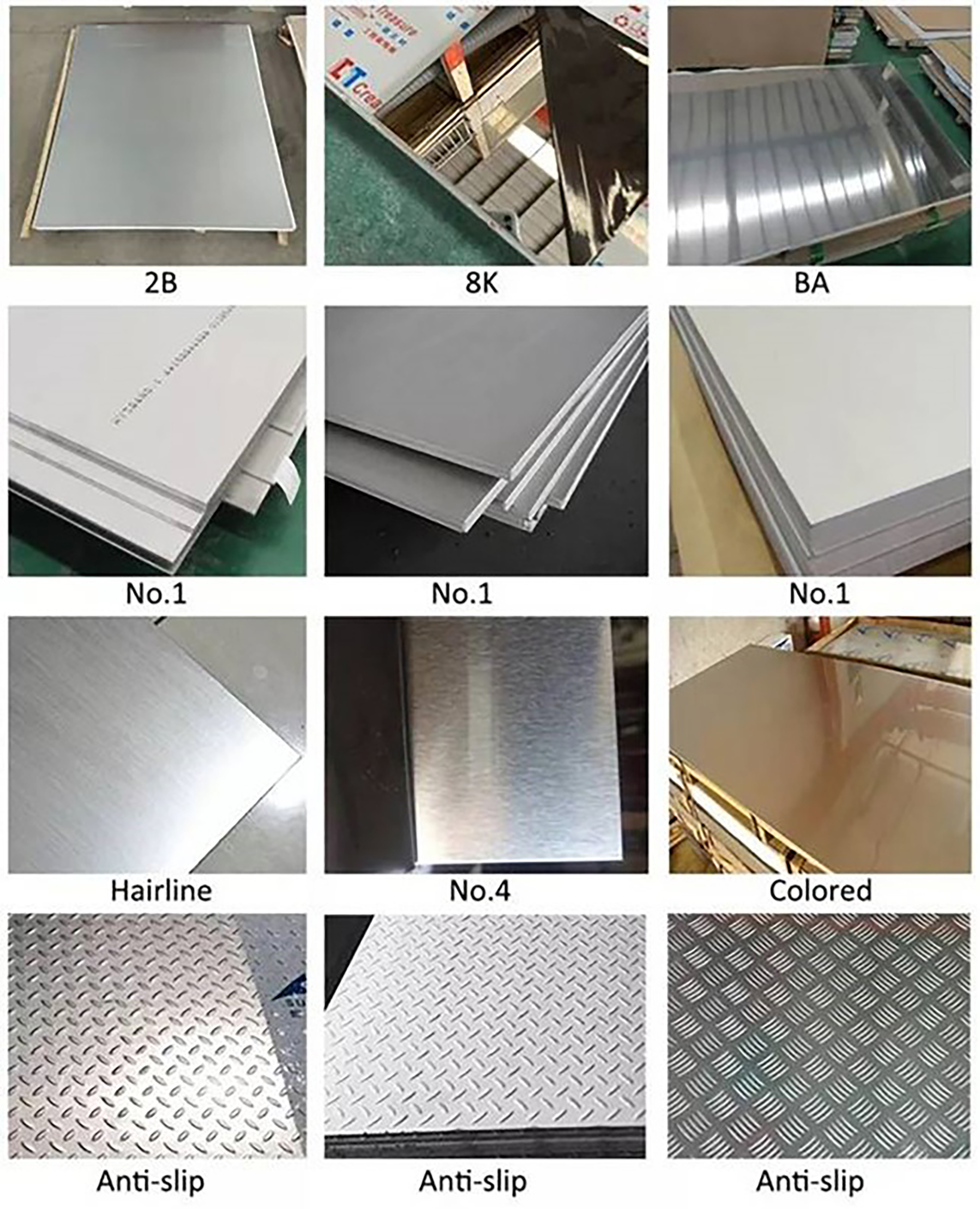

Surface

| No.4 | It has good gloss and fine lines on the surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 150 ~ 180 abrasive material (JIS R6002). |

| HL | It is silver-gray with hair streaks. Processing technology: Polish the 2D product or 2B product with a suitable size of abrasive material to make the surface appear continuous grain. |

| 8K | It is in a mirror state. Processing technology: 2D or 2B products are ground and polished to a mirror effect with a suitable abrasive material. |

| 2B | It is silvery white and better gloss and flatness than 2D surface. Processing technology: hot rolling + annealing shot peening pickling+ cold rolling + annealing pickling + quenching and tempering rolling. |

| BA | The surface gloss is excellent and has a high reflectivity, just like the mirror surface. Processing technology: hot rolling +annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenched and tempered rolling. |

| 1D | surface has discontinuous particles, also known as matte. Processing technology: hot rolling + annealing shot peening pickling +cold rolling + annealing pickling. |

| 2D | It is slightly shiny silvery white. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling. |

| No.3 | has better gloss and rough surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 100 ~ 120 abrasive materials (JIS R6002). |

| SB | The surface is smooth, the texture is clear, the texture is delicate, the appearance is comfortable, and the taste is high-grade.It is widely praised by consumers especially in kitchen appliances. |

Write your message here and send it to us

-2.jpg)

-2-150x150.jpg)

-2-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-1.jpg)

-2.jpg)

-2.jpg)

-2.jpg)

.jpg)