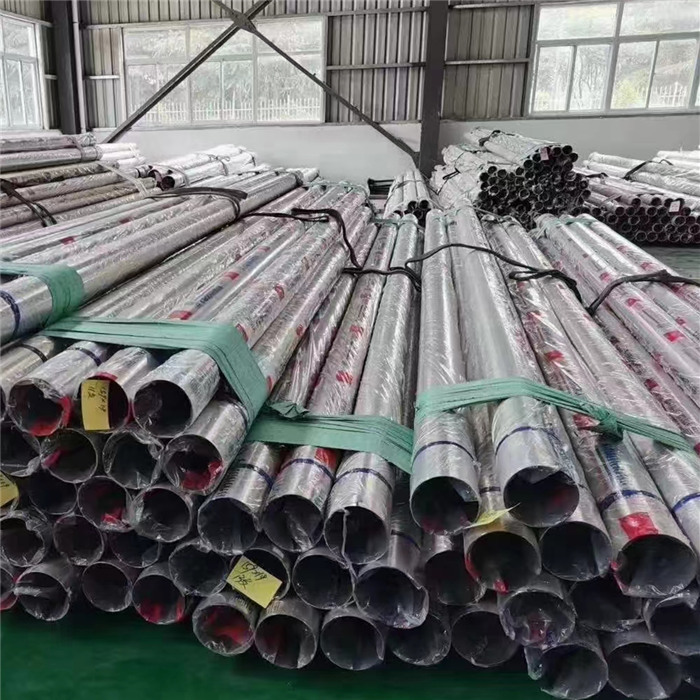

409 Stainless Steel Welded Pipe ASTM S40900 Stainless Steel Tube

Overview

With its excellent corrosion resistance, 409 stainless steel is suitable for prolonging the life of automobiles and lightening the weight of automobiles. As an environmentally friendly material for recycling, GM, Ford, Volkswagen, DaimlerChrysler and other major automobile manufacturers adopt 100% stainless steel in their exhaust systems.

Automobile exhaust system will be produced by the automobile engine high temperature, high speed combustion exhaust gas processing, it discharged outside the car.

The main function of the exhaust system is to reduce vibration and noise, and to convert the exhaust gas into a clean gas after it is reburned.

The automobile exhaust system is the longest part of the automobile parts, the system to withstand great temperature changes (-20 ~ 850℃) and high temperature, high speed exhaust gas of high frequency vibration, and in the car the largest change, the most complex environment, 409 can withstand the temperature limit of (-20 ~ 650℃).

Recently, due to environmental protection on the automobile exhaust standards increasingly strict, short distance urban driving increase, winter snow removal agent spread and other reasons, the use of exhaust system standards are increasingly strict, from the European Ⅱ- European standard, the traditional steel can not meet its technical requirements, high-end motorcycle exhaust system has been used 409 material.

The amount of 409 stainless steel used for each vehicle is 35KGS-65KGS.

Chemical Composition (%)

| C Carbon |

Mn Manganese |

P Phosphorus |

S Sulfur |

Si Silicon |

Cr Chromium |

Ni

Nickel |

| 0.08 | 1.0 | 0.045 | 0.03 | 1.0 | 10.5-11.75 | 0.5 |

Mechanical Properties

| Grade | 409 | |

| Density | 7.75 g/m³ | |

| Elastic Modulus (GPa) | 208 | |

| Mean Coefficient of Thermal Expansion (mm/m/°C) | 0-100°C | 11.0 |

| 0-315°C | 11.7 | |

| 0-538°C | 12.4 | |

| Thermal Conductivity (W/m.K) | at 100°C | 25.8 |

| at 500°C | 27.5 | |

| Specific Heat 0-100°C (J/kg.K) | 460 | |

| Electrical Resistivity (nW.m) | 600 |

Equivalent Material

| Grade | JIS | ISO | EN | UNS | BS |

| 409 | SUH409 | X2CrTi12 | 1.4512 | S40900 | 409S19 |

Production Process

Raw material - trimming - polishing - inspection (spray printing) - packaging - shipping (warehouse)

Raw material - heat treatment - correction - straightening - end trimming - pickling - water pressure test - inspection (printing) - packaging - shipping (warehouse)