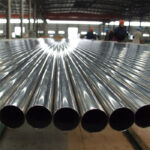

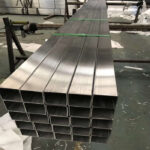

321 Stainless Steel Welded Pipe Stainless Tubing Coil Diameter 2 Inch

Overview

321 stainless steel ppe is a type of austenitic stainless steel with low carbon content and good corrosion resistance to many corrosive environments. 321 offers excellent weldability, good machinability and outstanding fabrication properties.

321 stainless steel pipe is commonly used in the chemical industry, pulp and paper industry, marine and offshore engineering industries as well as in the food and beverage industries.

321 stainless steel pipe also has a high level of resistance to chloride stress corrosion cracking and pitting. It is also resistant to hydrochloric acid at elevated temperatures up to 250°C (480°F).

Mechanical Properties Typical Values at 68°F (20°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 30,000 | 205 | 75,000 | 515 | 40 | 217 Brinell |

Fabrication Data

Alloy 321 stainless steel can be easily welded and processed by standard shop fabrication practices.

The alloy is quite ductile and forms easily.

The high sulfur content of Alloy 303 also has a detrimental impact on hot workability. If hot forming is required, once again, 304 should be considered as an alternate selection.

The cold work hardening rate of 321 stainless steel pipe makes it less machinable than 410 stainless steel, but similar to 304. The table below provides relevant machining data.

| Operation | Tool | Lubrication | Condition | |||||

| Depth

mm |

Depth

in |

Feed

mm/t |

Feed

in/t |

Speed

m/min |

Speed

ft/min |

|||

| Turning | High Speed Steel | Cutting Oil | 6 | .23 | 0.5 | .019 | 12-16 | 39-52 |

| Turning | High Speed Steel | Cutting Oil | 3 | .11 | 0.4 | .016 | 18-23 | 59-75 |

| Turning | High Speed Steel | Cutting Oil | 1 | .04 | 0.2 | .008 | 23-28 | 75-92 |

| Turning | Carbide | Dry or Cutting Oil | 6 | .23 | 0.5 | .019 | 67-76 | 220-249 |

| Turning | Carbide | Dry or Cutting Oil | 3 | .11 | 0.4 | .016 | 81-90 | 226-295 |

| Turning | Carbide | Dry or Cutting Oil | 1 | .04 | 0.2 | .008 | 99-108 | 325-354 |

| Depth of cut

mm |

Depth of cut

in |

Feed

mm/t |

Feed

in/t |

Speed

m/min |

Speed

ft/min |

|||

| Cutting | High Speed Steel | Cutting Oil | 1.5 | .06 | 0.03-0.05 | .0012-.0020 | 16-21 | 52-69 |

| Cutting | High Speed Steel | Cutting Oil | 3 | .11 | 0.04-0.06 | .0016-.0024 | 17-22 | 56-72 |

| Cutting | High Speed Steel | Cutting Oil | 6 | .23 | 0.05-0.07 | .0020-.0027 | 18-23 | 59-75 |

| Drill ø

mm |

Drill ø

in |

Feed

mm/t |

Feed

in/t |

Speed

m/min |

Speed

ft/min |

|||

| Drilling | High Speed Steel | Cutting Oil | 1.5 | .06 | 0.02-0.03 | .0007-.0012 | 9-13 | 29-42 |

| Drilling | High Speed Steel | Cutting Oil | 3 | .11 | 0.05-0.06 | .0020-.0024 | 11-15 | 36-49 |

| Drilling | High Speed Steel | Cutting Oil | 6 | .23 | 0.08-0.09 | .0031-.0035 | 11-15 | 36-49 |

| Drilling | High Speed Steel | Cutting Oil | 12 | .48 | 0.09-0.10 | .0035-.0039 | 11-15 | 36-49 |

| Feed

mm/t |

Feed

in/t |

Speed

m/min |

Speed

ft/min |

|||||

| Milling Profiling | High Speed Steel | Cutting Oil | 0.05-0.10 | .002-.004 | 11-21 | 36-69 | ||

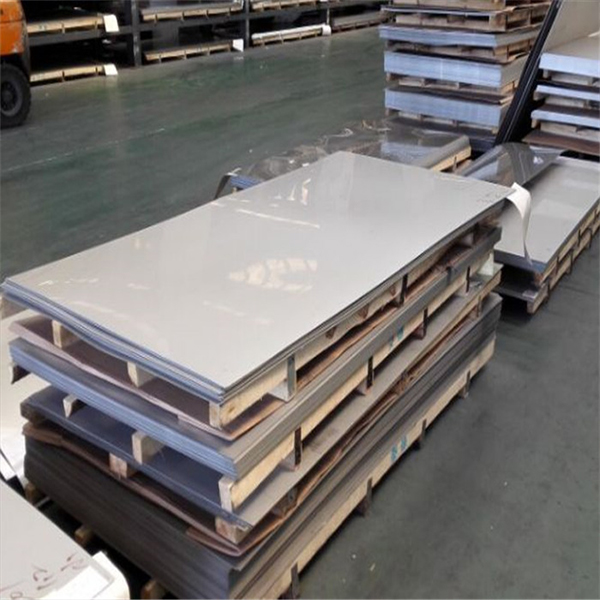

Alloy 321 stainless steel plate can be readily welded by most standard processes. A post weld heat treatment is not necessary.

.jpg)

-1.jpg)

-1.jpg)