321 Stainless Steel Sheet Coil Din 1.4541 Stainless Steel Coil

Characteristics

Alloy 321 (UNS S32100) is titanium stabilized austenitic stainless steel coil with good general corrosion resistance. It has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800 - 1500°F (427 - 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S 32109) stainless steel coil is the higher carbon (0.04 - 0.10) version of the alloy. It was developed for enhanced creep resistance and for higher strength at temperatures above 1000 ℉(537°C). In most instances, the carbon content of the plate enables dual certification.

Alloy 321 stainless steel coil cannot be hardened by heat treatment, only by cold working. It can be easily welded and processed by standard shop fabrication practices.

Chemical Analysis Weight %

(all values are maximum unless a range is otherwise indicated)

| Element | 321 | 321H |

| Chromium | 17.00 min.-19.00 max. | 17.00 min.-19.00 max. |

| Nickel | 9.00 min.-12.00 max. | 9.00 min.-12.00 max. |

| Carbon | 0.08 | 0.04 min.-0.14 max. |

| Manganese | 2.00 | 2.00 |

| Phosphorus | 0.045 | 0.045 |

| Sulfur | 0.03 | 0.03 |

| Silicon | 0.75 | 0.75 |

| Titanium | 5 x (C + N) min.-0.70 max. | 4 x (C + N) min.-0.70 max. |

| Nitrogen | 0.10 | 0.10 |

| Iron | Balance | Balance |

Features

321 stainless steel coil has better corrosion resistance than 304 and 316 types of stainless steels, which makes it ideal for use in corrosive environments.

321 stainless steel coil can be welded by all methods including arc welding ( TIG / GTAW ), electron beam welding ( EBW / EFW ), submerged arc welding ( SAW ) and laser beam welding ( LBIW ).

The strength levels of 321 stainless steel coils are up to 50% higher than those of 304 types of stainless steels and up to 80% higher than those of 316 types of stainless steels due to their increased carbon content and austenite grain size.

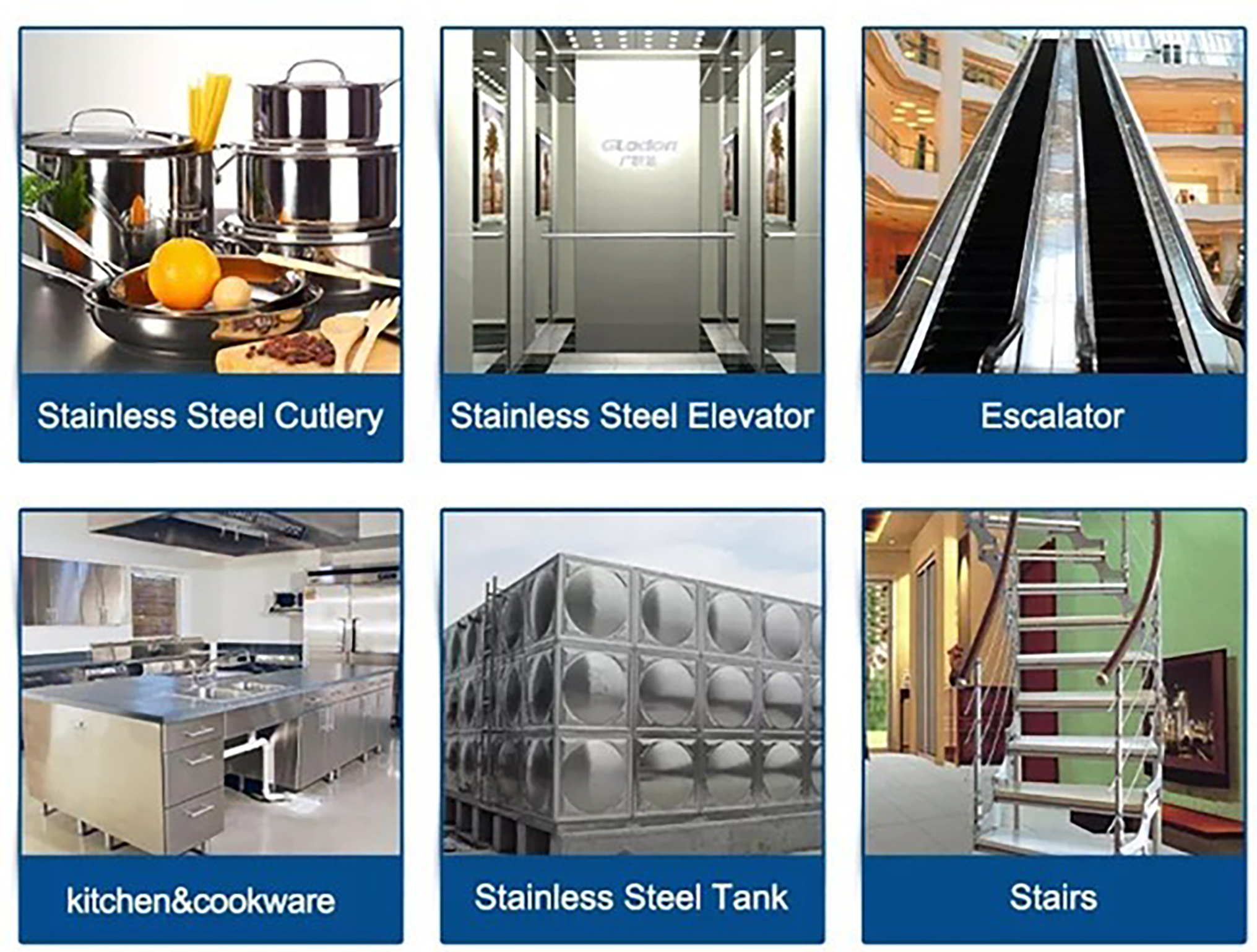

Applications

321 stainless steel coil is a free-machining austenitic chromium-nickel austenitic alloy (18% Cr, 12% Ni) that provides good corrosion resistance in a wide range of corrosive environments.

321 stainless steel coils are widely used in the chemical and petrochemical industries where its corrosion resistance properties can be put to good use. The alloy also finds application in marine environments where chloride stress corrosion cracking must be avoided. It is also used for food processing equipment such as food blenders and mixers, beverage dispensing equipment and heat exchangers.

-1.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

.jpg)

-1.jpg)