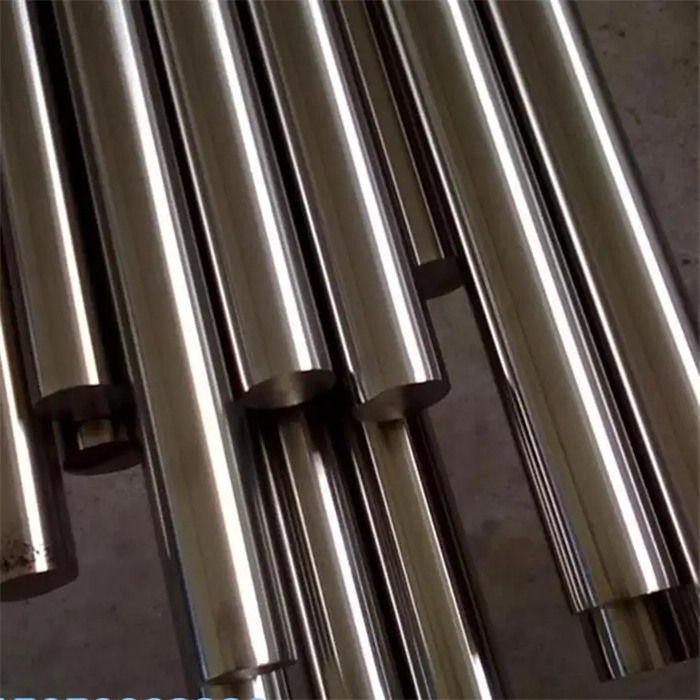

321 Stainless Steel Bars ASTM A276 321 Stainless Steel Round Rod

Advantages

321 stainless steel is Ni-Cr-Mo type austenitic stainless steel, equivalent to domestic grade 0Cr18Ni10Ti, its performance is very similar to 304, but due to the addition of titanium, the formation of chromium carbide is effectively controlled, so that it has a better resistance to grain boundary corrosion and high temperature strength.

321 austenitic stainless steel has good corrosion resistance in the atmosphere, and is widely used in petrochemical, electric power, bridge and automobile industries.

But the stainless steel "rust" is not absolute, because of the special service environment, stainless steel will also occur corrosion.

Medium concentration, pH value, temperature and other factors will have a greater impact on the corrosion resistance of stainless steel.

For example, in the range of 450~850℃ sensitization temperature long-term use, stainless steel will occur intergranular corrosion.

The mechanism is that C combines with Cr at grain boundary to form Cr23C6 and precipitates out, which reduces Cr content at grain boundary, which is the so-called "poor chromium".

The Cr element is one of the main elements to inhibit the intergranular corrosion. When the Cr content at the grain boundary is less than 12%, the probability of intergranular corrosion will increase.

Specifications

| Prodcut | 321 Stainless Steel Bar |

| Designation | 321 (1.4541 , SUS321 , S32100 , 06Cr18Ni11Ti) |

| Stanard | ASTM, ASME, AISI A 276 , SA 276, A 479, SA 479 |

| Diameter | 6mm to 630mm |

| Length | 1m to 6m |

| Finish | Bright, Polish, Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging, etc |

| Application | Chemical processing, food processing – equipment and storage, petroleum refining, catalytic cracking units, polythionic acid service, pharmaceutical production, waste heat recovery |

Mechanical Properties

| Grade | Yield Strength Rp0.2(N/mm²) | Tensile Strength Rm(N/mm²) | Hardness | Vickers Hardness(HV) | Elongation A50% |

| 321 | ≥205 | ≥520 | Annealed | ≤200 | ≥40 |

Mean Coefficient of Thermal Expansion

| Temperature Range | |||

| °F | °C | in/in °F | cm/cm °C |

| 68-212 | 20-100 | 9.2 x 10-6 | 16.0 x 10-6 |

| 68-1112 | 20-600 | 10.5 x 10-6 | 18.9 x 10-6 |

| 68-1832 | 20-1000 | 11.4 x 10-6 | 20.5 x 10-6 |

Test