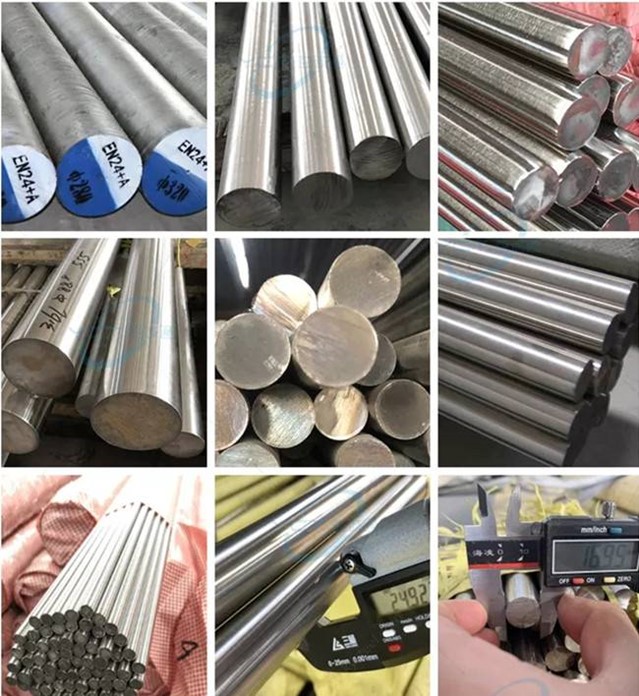

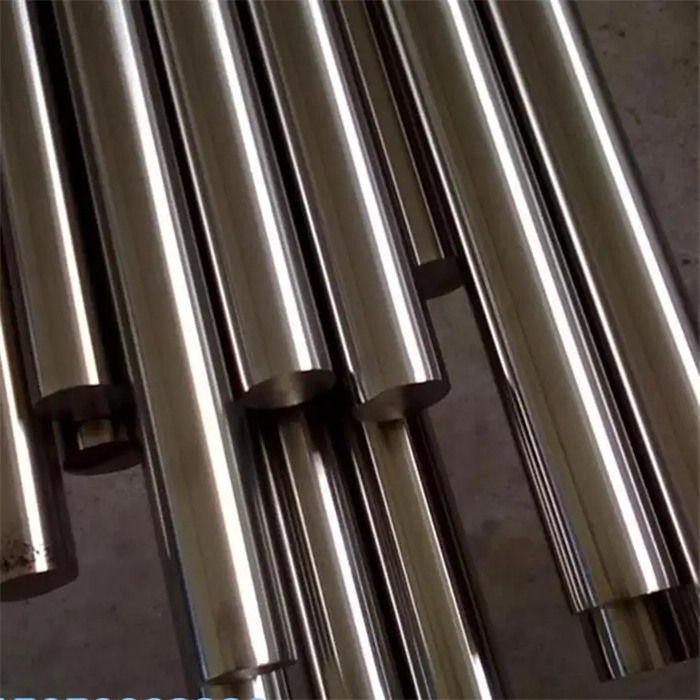

316L Stainless Steel Bars Cold Drawn Stainless Steel Round Rod

Advantages

316L has a wide range of applications in the chemical industry because of its excellent corrosion resistance. 316L is also a derivative of 18-8 austenitic stainless steel, with 2 ~ 3% Mo element added.

On the basis of 316L, many kinds of steel are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the content of Ni and Mo. Most of the existing 316L in the market are produced according to American standards.

For cost consideration, steel mills generally put the Ni content of products as far as possible by the lower limit. The American standard stipulates that the Ni content of 316L is 10 ~ 14%, while the Japanese standard stipulates that the Ni content of 316L is 12 ~ 15%. According to the minimum standard, there is a 2% difference between the American standard and Japanese standard in the Ni content, which is still quite huge in the price. Therefore, customers still need to see clearly when buying 316L products, whether the products refer to ASTM or JIS standards. The Mo content of 316L makes the steel have excellent pitting resistance and can be safely used in environments containing Cl- and other halogen ions.

Specifications

| Product | 316L Stainless Steel Bar |

| Material grade | 300 Series |

| Diameter | 6mm - 630mm or as customer’s requests |

| Length | 1000mm - 6000mm or as customer's request |

| Surface | Pickled, Black, Bright, Polishing |

| Standards | AISI , ASTM , JIS , SUS , GB |

| Certifications | ISO 9001 , SGS , BV |

| Delivery time | Usually 7-15 dyas, or upon negotiation |

| Payment terms | L/C at sight or T/T (30% as deposit) |

Mechanical Properties

| Grade | Yield Strength Rp0.2(N/mm²) | Tensile Strength Rm(N/mm²) | Hardness | Hardness

(HRB) |

Elongation A50% |

| 316L | ≥170 | ≥585 | Annealed | ≤95 | ≥40 |

FAQ

It’s easy to confuse 316 and 316L stainless steels, however a few key differences make 316L a more sought after stainless steel product. For one, the L indicates that this grade is the ultra low carbon variant. In this case, what is primarily a chromium and nickel based stainless product, the 316L variant also includes the addition of molybdenum, which is what gives this grade a particular advantage when it comes to highly corrosive environments.

It performs extremely well at temperatures up to 120°F.

Marine grade stainless steels are specifically engineered to withstand highly corrosive environments, like where high concentrations of acids are present.

You might notice the letters L, F, N, or H following some stainless steels and wonder what these letters mean. These letters indicate slight differences in chemical composition and suggest how a particular stainless steel grade should be used. In the case of 316L, the L indicates that there is less carbon than is found in the 316 grade. It is considered the “ultra low” carbon variant.