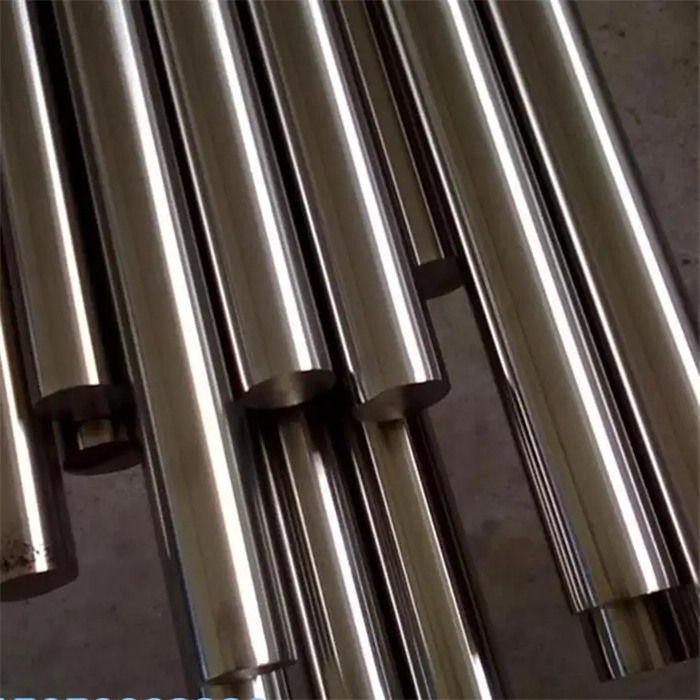

310S Stainless Steel Bars 310S Bright Polished Surface Round Bod

Advantages

310S (UNS S31008) is the low carbon version of the alloy. It is utilized for ease of fabrication. 310H (UNS S31009) is a high carbon modification developed for enhanced creep resistance. In most instances the grain size and carbon content of the plate can meet both the 310S and 310H requirements.

Alloy 310 can be easily welded and processed by standard shop fabrication practices.

Melting point 1470℃, 800℃ began to soften, allowable stress continued to reduce.

Improve the common carbon tool steels brittle nature, and to extend the life of tools.

Vacuum degassing refining steel, stable quality.

Good hardenability, oil cold hardening (quenching and deformation less) good toughness and wear resistance, durable tools.

Specifications

| Product | 310S Stainless Steel Bar |

| Standard | ASTM, AIS, SUS, JIS, EN, DIN, GB, ASME, etc |

| Out Diameter | 6mm to 630mm or as your requirement |

| Length | 5.8m, 6m or as your requirement |

| Tolerance | Outer Diameter:+/-0.1mm, Thickness:+/-0.01mm, Length:+/-1mm |

| Surface | Hot Rolled Pickled or Sand Blasting Finished

Peel turned (PT) Bright Peel turned and burnished (PTB) Rough machined (RM) Cold Drawn Hairline Polished |

| Technique | Cold Rolled, Hot Rolled, Forged Round Bar, Cold Drawn |

| Heat Treatment | Solution Annealing, Soft Annealing, Hardening & Tempering & Normalizing, Oil & Water Quenching. |

| Features | Chemical resistance

Dimensional accuracy Durable High strength Corrosion resistance |

| Application | Decoration construction, upholstery, industry instrument |

| Certification | SGS,TUV,ISO |

Physical Properties

| Specific Heat | 0.12 BTU/lb-°F (32 – 212°F) 502 J/kg-°K (0 – 100°C) |

| Modulus of Elasticity | 28.5 x 106 psi 196 GPa |

| Thermal Conductivity 212°F (100°C) | 8.0 BTU/hr/ft2/ft/°F 10.8 W/m-°K |

| Melting Range | 2470 – 2555°F 1354 – 1402°C |

| Electrical Resistivity | 30.7 Microhm-in at 68°C 78.0 Microhm-cm at 20°C |

Standard

| ASTM A276 | This specification encompasses cold-finished or hot-finished bars, including rounds, squares, and hexagons, and hot-rolled or extruded shapes, such as angles, tees, and channels in the more commonly used types of stainless steels. |

| ASTM A479 | This specification includes cold and hot finished stainless steel bars, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels. |

| ASTM A484 | This specification includes wrought stainless steel bars, shapes, forgings, and billets or other semi-finished materials, except wire, for forging. The materials are available in four types of conditions. |

| ASTM A582 | This specification includes cold or hot finished bars, which are suitable for machining processes. This specification includes rounds, squares, and hexagons, from common types of stainless free-machining steels. |

| ASTM B473 | This specification includes nickel alloy bar & wire, which can be produced in a solution-annealed condition, stabilized-annealed condition, or annealed condition. |