309S 310S Stainless Steel Seamless Tubes Pipe Hot Rolled

Overview

Alloy 309 (UNS S30900) is an austenitic stainless steel developed for use in high temperature corrosion resistance applications. The alloy resists oxidation up to 1900°F (1038°C) under non-cyclic conditions. Frequent thermal cycling reduces oxidation resistance to approximately 1850°F (1010°C).

Because of its high chromium and low nickel content, Alloy 309 can be utilized in sulfur containing atmospheres up to 1832°F (1000°C). The alloy is not recommended for use in highly carburizing atmospheres since it exhibits only moderate resistance to carbon absorption. Alloy 309 can be utilized in slightly oxidizing, nitriding, cementing and thermal cycling applications, albeit, the maximum service temperature must be reduced.

When heated between 1202 – 1742°F (650 – 950°C) the alloy is subject to sigma phase precipitation. A solution annealing treatment at 2012 – 2102°F (1100 – 1150°C) will restore a degree of toughness.

Creep Properties

| Temperature | Creep Strain (MPa) | Creep Rapture (MPa) | |||||

| °C | °F | 1000 H | 10000 H | 100000 H | 1000 H | 10000 H | 100000 H |

| 600 | 1112 | 120 | 80 | 40 | 190 | 120 | 65 |

| 700 | 1292 | 50 | 25 | 20 | 75 | 36 | 16 |

| 800 | 1472 | 20 | 10 | 8 | 35 | 18 | 7.5 |

| 900 | 1652 | 8 | 4 | 3 | 15 | 8.5 | 3 |

| 1000 | 1832 | 4 | 2.5 | 1.5 | 8 | 4 | 1.5 |

Physical Properties

| Specific Heat | 0.12 BTU/lb-°F (32 – 212°F) 502 J/kg-°K (0 – 100°C) |

| Modulus of Elasticity | 28.5 x 106 psi 193 GPa |

| Thermal Conductivity 212°F (100°C) | 9.0 BTU/hr/ft2/ft/°F 15.6 W/m-°K |

| Melting Range | 2500 – 2590°F 1480 – 1530°C |

| Electrical Resistivity | 30.7 Microhm-in at 68°C 78 Microhm-cm at 20°C |

Fabrication Data

Alloy 309S can be easily welded and processed by standard shop fabrication practices.

Heat uniformly at 1742 – 2192°F (950 – 1200°C). After hot forming a final anneal at 1832 – 2101°F (1000 – 1150°C) followed by rapid quenching is recommended.

The alloy is quite ductile and forms in a manner very similar to 316. Cold forming of pieces with long-term exposure to high temperatures is not recommended since the alloy is subject to carbide precipitation and sigma phase precipitants.

Alloy 309S can be readily welded by most standard processes including TIG, PLASMA, MIG, SMAW, SAW and FCAW.

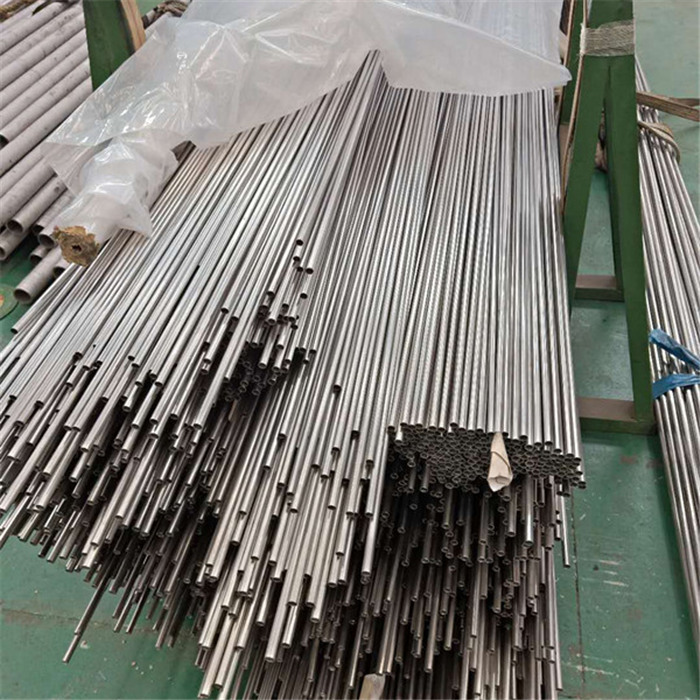

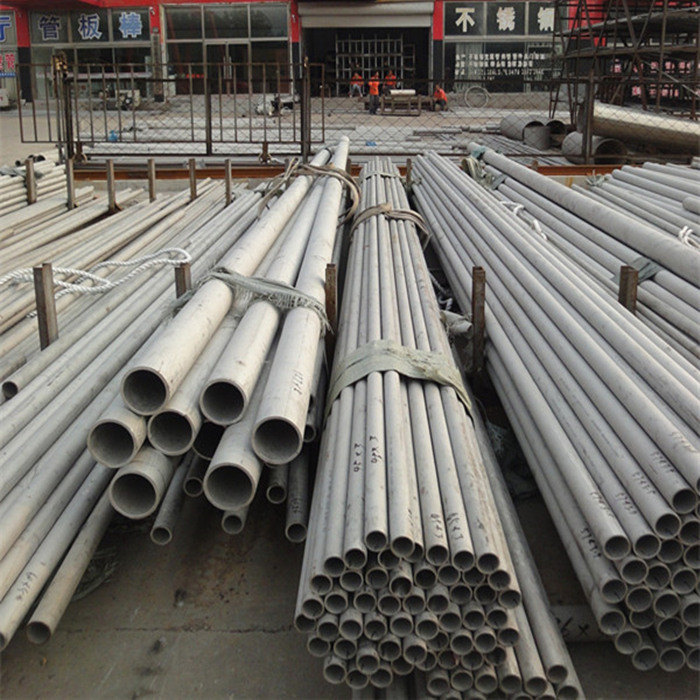

Packing

309 Stainless Steel Seamless Tube is sleeved into plastic bag individually, pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation. SS 309 ASTM A312 Seamless Tube packing will be according to international standard in bundles strapped by strips then into containers to avoid any damage.

-2.jpg)