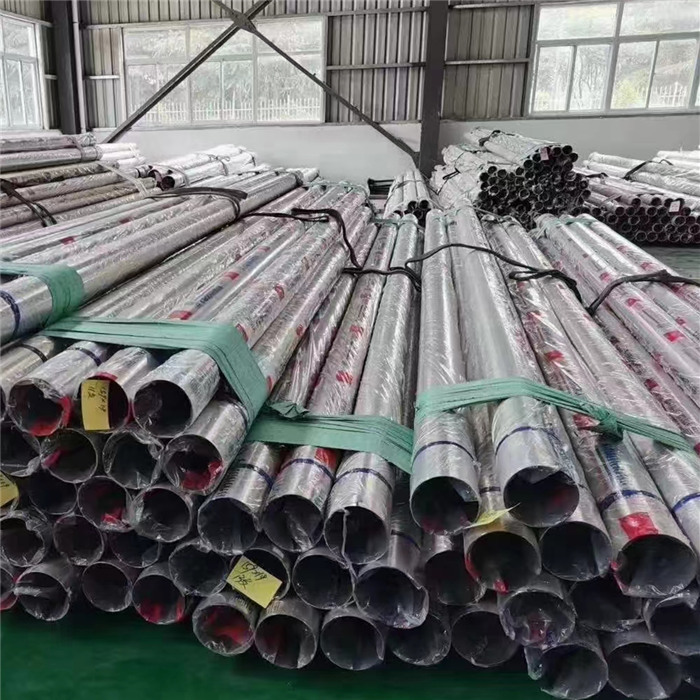

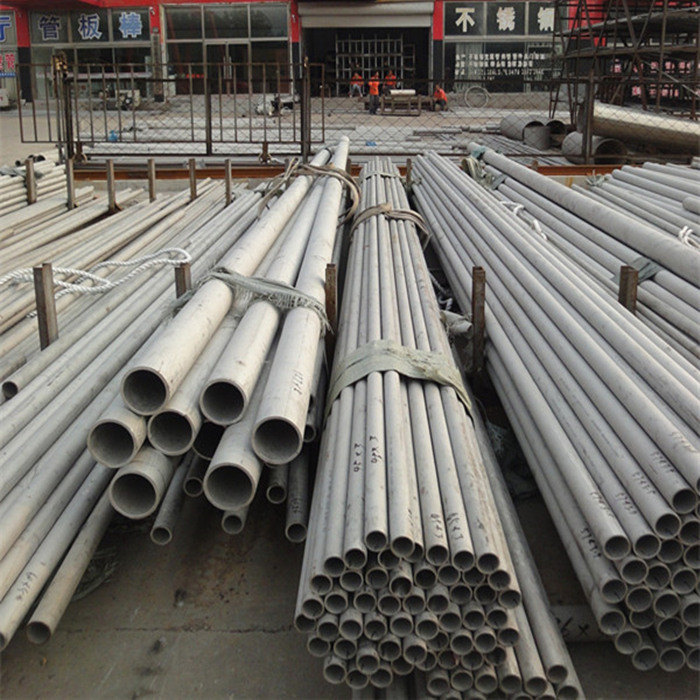

304 Stainless Steel Welded Pipe Food Grade 304 Stainless Steel Pipe

Overview

304 stainless steel pipe is a type of austenitic stainless steel with a minimum of 18% chromium, 8% nickel, and a maximum of 0.08% carbon.

It has excellent corrosion resistance in many environments, including fresh water, seawater, wastewater, acids and alkalies. It can be used for food processing and handling equipment such as tanks and heat exchangers.

These pipes are made from annealed and pickled sheet, which gives them their ability to be shaped into any number of products. 304 stainless steel is an excellent choice for use in harsh environments where corrosion resistance is needed. This type of steel has a high resistance to rusting and oxidation, making it perfect for outdoor applications such as fencing or railings. It also has good resistance to pitting and crevice corrosion, which makes it a strong choice for marine environments.

Chemical Composition (%)

| C Carbon |

Mn Manganese |

P Phosphorus |

S Sulfur |

Si Silicon |

Cr Chromium |

Ni Nickel |

| 0.08 | 2 | 0.045 | 0.03 | 1.0 | 18.00-20.00 | 8.00-11 |

Advantages (Resistance Welding)

During spot welding, the general spot welder can weld 60 points per minute. If the fast spot welder is used

More than 500 points per minute; Butt welding bar with diameter of 40mm can weld one joint per minute; Seam welding

When the thickness of the thin plate is 1-3mm, the welding speed is usually 0.5-lm / min, and the rolling butt welding is the highest

The connection speed can reach 60m / min. Therefore, resistance welding is very suitable for mass production.

For welded joints, the metallurgical process is simple, and it is not easily affected by air

Harmful effect, so the chemical composition of the welded joint is uniform and basically consistent with the base metal. From the whole knot

From the perspective of structure, due to the concentration of heat, small heating range and small heat affected zone, the welding deformation is not large and is easy to control. In addition, during spot and seam welding, because the welding spot is inside the weldment, the weld surface is flat and smooth

Therefore, the surface quality of the weldment is also good.

Resistance welding does not use welding materials and generally does not use shielding gas, so

Under normal circumstances, there is little consumption except for the necessary power consumption, so the use cost is low.

Resistance welding will not produce harmful gas or strong light radiation, so

The labor conditions are better. In addition, the resistance welding process is simple and easy to realize mechanization and automation. Therefore, the labor intensity of workers is low.

-2.jpg)