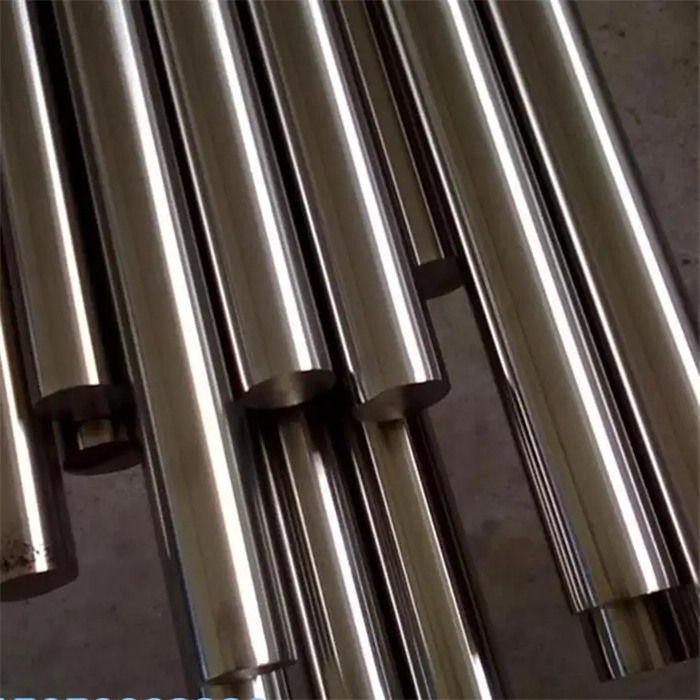

304 Stainless Steel Round Bars Polished 10mm 16mm 18mm 20mm 24mm

Advantages

304 stainless steel has excellent corrosion resistance and good resistance to intergranular corrosion. It is often used in the medical industry because of its resistance to many different chemicals and its durability under high levels of heat. This makes it ideal for use in surgical instruments and other items that come into contact with human blood or bodily fluids. It can also be used in food processing equipment because it does not leach ions into food products as some other metals do. 304 is the most cost effective grade of steel. So the 304 stainless steel bar price is lower compared to other grades of stainless steels and all metallic products in general.

Corrosion Resistance

Alloy 304 has good resistance to atmospheric corrosion, foods and beverages and to many organic and inorganic chemicals in moderately oxidizing to moderately reducing environments. The high chromium content of the alloy provides resistance to oxidizing solutions such as nitric acid up to 55% weight and up to 176°F (80°C).

Alloy 304 also resists moderately aggressive organic acids such as acetic. The nickel present in the alloy provides resistance to moderately reducing solutions such as pure phosphoric acid, whatever the concentration, in cold solutions and up to 10% diluted hot solutions. The alloy can also operate successfully in caustic solutions free of chlorides or Alloy 304 does not perform well in more highly reducing environments such as those containing chlorides and sulfuric acid.

Alloy 304 performs well in fresh water service with low levels of chlorides (less than 100ppm). At higher chloride levels the grade is susceptible to crevice corrosion and pitting. For successful performance under these more severe conditions, higher molybdenum content is need such as 316/316L. Alloy 304 is not recommended for service in marine environments.

In most instances, the corrosion resistance of Alloys 304, 304L and 304H will be roughly equal in most corrosive environments. However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones Alloy 304L should be used because of its low carbon content.

Lowest Temperature (°F) at Which the Corrosion Rate Exceeds 5mpy

|

Corrosion Environment |

Type 304 |

Type 316L |

2205 (UNS S32205) |

2507 |

| 0.2% Hydrochloric Acid | >Boiling | >Boiling | >Boiling | >Boiling |

| 1% Hydrochloric Acid | 86p | 86 | 185 | >Boiling |

| 10% Sulfuric Acid | — | 122 | 140 | 167 |

| 60% Sulfuric Acid | — | <54 | <59 | <57 |

| 96% Sulfuric Acid | — | 113 | 77 | 86 |

| 85% Phosphoric Acid | 176 | 203 | 194 | 203 |

| 10% Nitric Acid | >Boiling | >Boiling | >Boiling | >Boiling |

| 65% Niitric Acid | 212 | 212 | 221 | 230 |

| 80% Acetic Acid | 212p | >Boiling | >Boiling | >Boiling |

| 50% Formic Acid | ≤50 | 104 | 194 | 194 |

| 50% Sodium Hydroxide | 185 | 194 | 194 | 230 |

| 83% Phosphoric Acid + 2% Hydrofluoric Acid |

113 | 149 | 122 | 140 |

| 60% Nitric Acid + 2% Hydrocloric Acid |

>140 | >140 | >140 | >140 |

| 50% Acetic Acid + 50% Acetic Anhydride |

>Boiling | 248 | 212 | 230 |

| 1% Hydrochloric Acid + 0.3% Ferric Chloride |

68p | 77p | 113ps | 203ps |

| 10% Sulfuric Acid + 2000ppm Cl- + N2 |

— | 77 | 95 | 122 |

|

10% Sulfuric Acid + |

— | <<59p | <59 | 104 |

| WPA1, High Cl- Content | <<50 | ≤50 | 113 | 203 |

| WPA2, High F- Content | <<50 | ≤50 | 140 | 167 |

ps = pitting can occur

ps = pitting/crevice corrosion can occur

| WPA | P2O5 | CL- | F- | H2SO4 | Fe2O3 | Al2O3 | SiO2 | CaO | MgO |

| 1 | 54 | 0.20 | 0.50 | 4.0 | 0.30 | 0.20 | 0.10 | 0.20 | 0.70 |

| 2 | 54 | 0.02 | 2.0 | 4.0 | 0.30 | 0.20 | 0.10 | 0.20 | 0.70 |