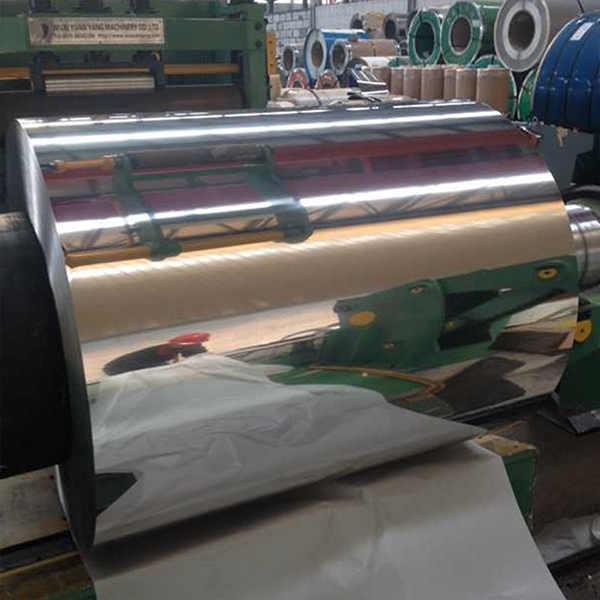

2507 Stainless Steel Strips Cold Rolled Stainless Steel Strip Coil

Features

Chemical Composition (%)

| Element | Minimum percentage | Maximum percentage |

| C | – | 0.03 |

| Si | – | 0.8 |

| Mn | – | 1.2 |

| P | – | 0.035 |

| S | – | 0.02 |

| Cr | 24 | 26 |

| Mo | 3 | 5 |

| Ni | 6 | 8 |

| N | 0.24 | 0.32 |

Toughness Values

(KCV Minimum Values)

| Temp. | -50°C | +20°C | -60°F | +70°F |

| Single | 75 J/cm_ | 90 J/cm_ | 54 ft. lbs | 65 ft. lbs |

| Average (5) | 90 J/cm_ | 150 J/cm | 65 ft. lbs | 87 ft. lbs |

Hardness

(Typical Values)

| Average (5) | HV10 180-230 | HB : 180-230 | HRC _ 20 |

Processing Method

2507 should be hot worked between 1875°F and 2250°F. This should be followed by a solution anneal at 1925°F minimum and a rapid air or water quench.

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austenitic steels so fabricators may find that higher forming forces, increased radius of bending, and increased allowance for springback are necessary. Deep drawing, stretch forming, and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

2507 should be solution annealed and quenched after either hot or cold forming. Solution annealing should be done at a minimum of 1925°F. Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), plasma arc welding (PAW), flux cored wire (FCW), or submerged arc welding (SAW). 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure.

Preheating of 2507 is not necessary except to prevent condensation on cold metal. The interpass weld temperature should not exceed 300°F or the weld integrity can be adversely affected. The root should be shielded with argon or 90% N2/10% H2 purging gas for maximum corrosion resistance. The latter provides better corrosion resistance.

If welding is to be done on only one surface and post-weld cleaning is not possible, GTAW is suggested for root passes. GTAW or PAW should not be done without a filler metal unless post-weld cleanup is possible. A heat input of 5-38 kJ/in. should be used for SMAW or GTAW. A heat input of about 50kJ/in. can be used for SAW.

-1.jpg)

-1-150x150.jpg)

-2-150x150.jpg)

-2-150x150.jpg)

-1-150x150.jpg)

-1-150x150.jpg)

-3.jpg)