2205 Stainless Steel Seamless Tubes Pipe Super Duplex

Overview

The yield strength of 2205 duplex stainless steel is more than double that of ordinary austenitic stainless steel. This characteristic allows designers to reduce weight when designing products, giving this alloy a price advantage over 316, 317L.

The corrosion resistance properties of duplex 2205 tube is much better as compared to alloy grade 316. The ASTM A790 duplex 2205 tube produced under this specification are intended to be used for those applications where corrosion resistance is a primary concern. Although a lot of emphases has been given to the ability of the ASTM A790 specified 2205 stainless steel tube ability to resist stress related corrosion cracking.

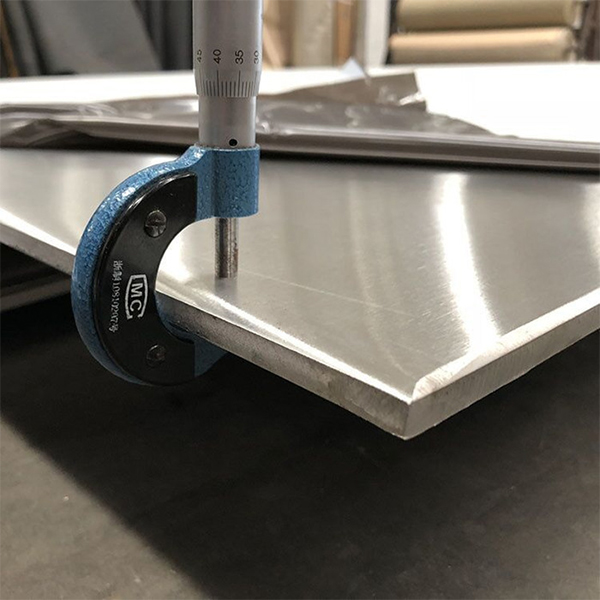

The 2205 duplex stainless tube produced in accordance to ASTM A790 specification could be constructed by either a seamless construction or an automatic welding process. If the 22cr duplex tube is to be welded, no filler metal is required to be added to the alloy during its welding process. Heat and product analysis is to be performed on the SA 789 alloy 2205 tube material.

Physical Properties

| Temperature °F | 68 | 212 | 392 | 572 | |

| Density | lb/in3 | 0.278 | — | — | — |

| Modulus of Elasticity | psi x 106 | 27.6 | 26.1 | 25.4 | 24.9 |

| Linear Expansion (68°F-T) | 10-6/°F | — | 7.5 | 7.8 | 8.1 |

| Thermal Conductivity | Btu/h ft°F | 8.7 | 9.2 | 9.8 | 10.4 |

| Heat Capacity | Btu/lb ft°F | 0.112 | 0.119 | 0.127 | 0.134 |

| Electrical Resistivity | Ωin x 10-6 | 33.5 | 35.4 | 37.4 | 39.4 |

Structure

The chemical analysis of 2205 duplex stainless steel tube is optimized to obtain a typical 50 a/ 50 g microstructure after solution annealing treatment at 1900°/1922°F (1040°/1080°C).

The pitting resistance of an austenitic stainless steel can be related directly to alloy composition, where chromium, molybdenum and nitrogen are a weight %. The Pitting Resistance Equivalent Number (PREN) uses the following formula to measure an alloy's relative pitting resistance - the higher the number, the better the pitting resistance.

Widely used in petroleum, chemical, medical, food, light industry, Industrial pipes and mechanical structural parts such as mechanical meters. In addition, when the bending and torsion strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts. And engineering structure.It is also often used as furniture and kitchen utensils.

-2.jpg)

-2.jpg)

-2.jpg)

-1.jpg)