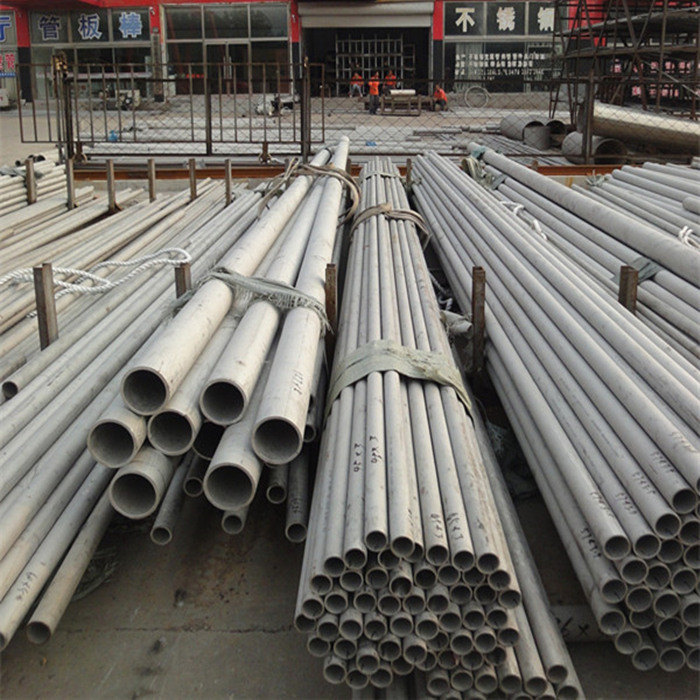

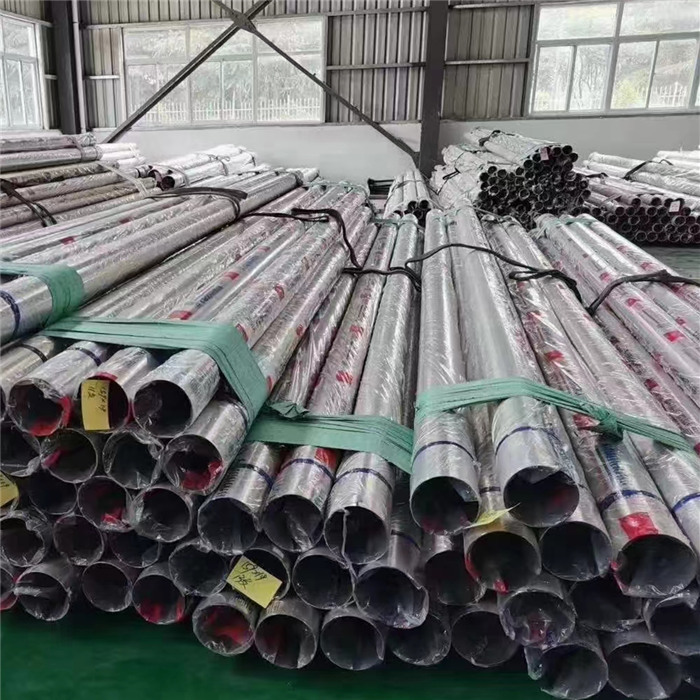

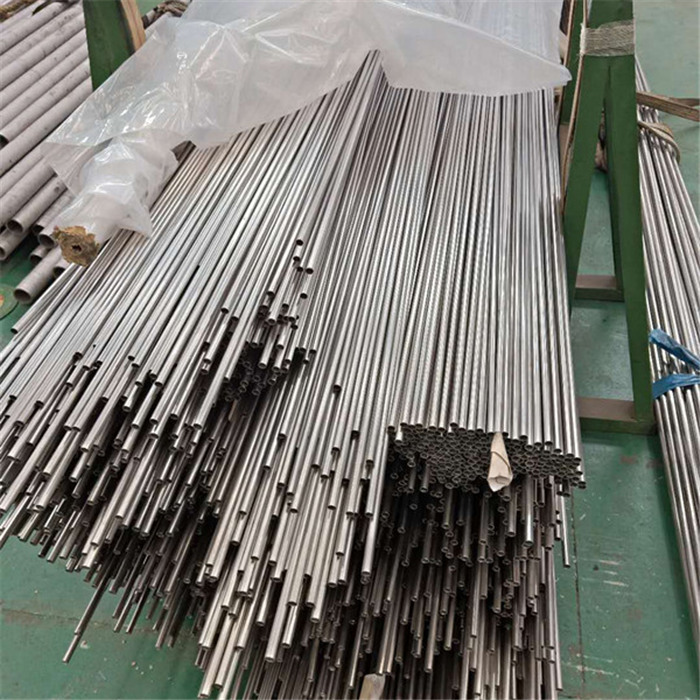

201 Stainless Steel Welded Pipe Tube For Decoration Application

Overview

201 stainless steel is an austenitic nickel-chromium-maganese stainless steel which has a certain acid resistance, alkali resistance, high density, polishing no bubble, no pinhole and other characteristics, is the production of all kinds of watchcase, watchband bottom cover quality materials. Mainly used for decorative pipe, industrial pipe, some shallow stretching products.

Because the 201 stainless steel pipe is only slightly harder than 304, the elongation is worse than 304, deep drawing will crack, but in the decorative welded pipe industry, these do not affect the use.

201 stainless steel pipe is acid - and alkali-resistant steel pipe prepared for round steel. 201 stainless steel pipe has formability, good corrosion resistance, and fabricability.

201 stainless steel welded pipe is also called stainless steel decorative pipe. Normally produced from 201 stainless steel strips by welding, including round pipe and rectangle pipe. 201 stainless steel pipe the outer surface normally be mirror polished.

Chemical Composition (%)

| C Carbon |

Mn Manganese |

P Phosphorus |

S Sulfur |

Si Silicon |

Cr Chromium |

Ni

Nickel |

Cu

Copper |

N

Nitrogen |

| 0.15 | 5.5-7.5 | 0.06 | 0.03 | 0.8 | 16.0-18.0 | 0.8-1.5 | 0.8-1.5 | 0.25 |

Equivalent Material

| Grade | UNS | GB | JIS | ASTM |

| 201 | S201 | 1Cr17Mn6Ni5N(old)

12Cr17Mn6Ni5N (new) |

SUS201 | 201 |

Material Classification

this is the high-end product of the J series. Suitable for small Angle type of deep drawing products. It is the choice of most products that require deep salt extraction and salt spray testing. For example, sinks, kitchen utensils, bathroom products, water bottles, vacuum bottles, door hinges, shackles, etc.

slightly higher carbon content than J4, lower copper content than J4. Its processing performance is lower than J4. Suitable for decorative board, bathroom products, sink, product tube and other ordinary shallow drawing products.

for decorative pipes. You can do simple things on the decorative panel, but it's hard to do. The feedback is that the shear plate is bent and has an internal seam after breaking (black titanium, color plate series, polished plate, broken, with internal seam folding). The receiver material has been tried to bend 90 degrees but will not continue.

Decorative tubes: simple decorative tubes are still good because they are harder (both above 96°) and more polished, but square or bent tubes (90°) break easily.

In the case of the plate: due to the high hardness, the plate surface beautiful, can accept grinding, polishing and electroplating and other surface treatment. But the biggest problem is bending, bending tends to break, and grooves tend to break. Poor scalability.

-3.jpg)